When it comes to maize milling, the intake process is the starting line for efficiency, hygiene and product quality. Whether you’re scaling up a commercial operation or launching a start-up mill, choosing between bulk and bagged maize intake systems is a decision that impacts your bottom line and operational success.

In this article, we compare the cost, hygiene and speed of bulk and bagged intake systems to help you make an informed decision. We’ll also highlight Roff’s turnkey solutions tailored for African conditions.

1. Cost comparison: Bulk vs bagged intake

Bagged intake: Lower start-up cost, higher operational expense

Bagged maize intake is often the go-to for smaller mills and start-ups due to its lower initial infrastructure costs. You don’t need specialised silos, conveyors or intake pits – just a receiving area and labour for manual unloading.

However, this model becomes costlier over time:

- Labour-intensive: requires more hands to unload and move bags.

- Wastage risk: higher chance of spillage and losses during handling.

- Storage inefficiencies: more space required and higher likelihood of pest exposure.

Bulk intake: Higher initial investment, long-term savings

Bulk systems demand upfront investment in intake pits, silos and conveyors. But the payback is significant:

- Lower labour costs: mechanised intake means fewer hands needed.

- Reduced losses: less spillage and better inventory control.

- Higher throughput: intake processes are faster and more consistent.

Bottom line: Once your mill consistently runs above ±2 t of maize per hour, the lower labour bill and reduced spillage of a bulk system usually offset its higher capital cost within three to five years, even at Sub-Saharan wage levels.

2. Hygiene and food safety

Bagged intake: Higher contamination risk

Maize in bags is exposed to multiple handling points during its journey from farm to mill. Each touchpoint increases the risk of:

- Mould growth due to poor storage.

- Physical contaminants like stones or metal.

- Pest infestation from storage facilities.

Because bags are often reused or stored improperly, foreign matter is common, impacting product quality and safety. Studies in West Africa report post-harvest bag losses of 15–30 % from insects alone unless hermetic bags are used.

Bulk intake: Better control, cleaner process

A bulk system allows for more controlled hygiene conditions:

- Sealed silos prevent pest entry.

- Pre-cleaning systems remove foreign materials before milling.

- Better moisture monitoring reduces mould risk.

Modern HACCP-compliant mills favour bulk systems for their reduced risk of cross-contamination and more consistent quality.

Bottom line: For cleaner, safer maize, bulk intake is the superior option.

3. Speed and efficiency

Bagged intake: Manual and time-consuming

Offloading bags, weighing and manually moving maize to storage takes time. Bottlenecks are common, especially when:

- Deliveries arrive at peak hours.

- There’s a shortage of labour.

- Bad weather affects open receiving areas.

This reduces overall milling efficiency and increases turnaround time.

Bulk intake: Fast and consistent

A bulk system operates with mechanised augers or screw conveyors that can intake up to 40 tons/hour or more, depending on the configuration.

- Integrated with weighbridges and pre-cleaners.

- Faster turnaround for delivery trucks.

- Enables 24/7 intake without labour fatigue. Automated pits and weighbridges keep trucks moving even on night shifts when staff numbers are low.

- Moisture control with aeration cooling.

Bottom line: Bulk systems ensure higher throughput, fewer delays and better planning.

4. Space and infrastructure

Bagged intake: More floor space, less infrastructure

Bag storage requires more floor area and increases fire and pest risk. However, you avoid the need for costly pits and conveyor systems.

Bulk intake: Vertical storage, smart footprint

Silos use vertical space and can store large volumes more hygienically. The infrastructure can be designed to suit your site layout for optimal logistics.

Bottom line: Bulk intake is more space-efficient over time and easier to secure against loss and contamination.

5. Flexibility and scalability

Bagged intake: Good for low-volume, localised supply

Smaller mills, especially in rural or community-based settings, benefit from the flexibility of bagged maize intake. It suits local sourcing and smaller batch production.

Bulk intake: Ideal for growth and expansion

Once you scale operations, bulk systems allow for easy integration with automated processes like:

- Silo level sensors

- PLC-controlled cleaning

- Real-time stock monitoring

Bottom line: Bagged intake suits short-term goals, while bulk systems prepare your business for long-term success.

6. Supply chain realities in sub-Saharan Africa

Understanding local supply chains is essential for choosing the right intake system. The realities in Sub-Saharan Africa can significantly influence both cost and operational efficiency.

Sourcing maize: Bulk vs bagged

Bulk maize availability:

- More common near large commercial farms, cooperatives, or regions with established grain silos.

- In remote or rural areas, bulk supply may be limited, making bagged maize the default option.

Bagged maize:

- Widely available in local markets and from smallholder farmers.

- Offers flexibility for mills sourcing from diverse, small-scale suppliers.

Logistics and Infrastructure

Transport: Bulk maize requires specialised trucks and unloading facilities, which may not be available in all regions. Bagged maize can be transported using standard vehicles, but is more labour-intensive to handle.

Storage: Bulk storage (silos) is more efficient but demands reliable electricity and pest control. Bagged storage is simpler but increases risk of losses from pests, moisture, and theft.

Market and price volatility

- Maize prices can fluctuate seasonally and regionally.

- Bulk purchases may secure better prices but require larger upfront capital.

- Bagged purchases offer flexibility but may be more expensive per ton due to smaller quantities and higher handling costs.

Practical considerations for entrepreneurs

Urban/Peri-Urban Mills: Likely to benefit from bulk intake due to proximity to suppliers and infrastructure.

Rural/Community Mills: May need to start with bagged intake, transitioning to bulk as supply chains and operations mature.

Hybrid Approach: Some mills use both systems, starting with bagged intake and adding bulk capabilities as they scale.

Linking the right Roff equipment to the right intake

Roff offers a range of milling solutions that align with both intake types:

For bagged intake start-ups:

- SP-1 Maize Mill: Designed for entrepreneurs, it allows efficient processing with minimal infrastructure.

- Roff Grain Crushers: Ideal for feed production from manually bagged maize.

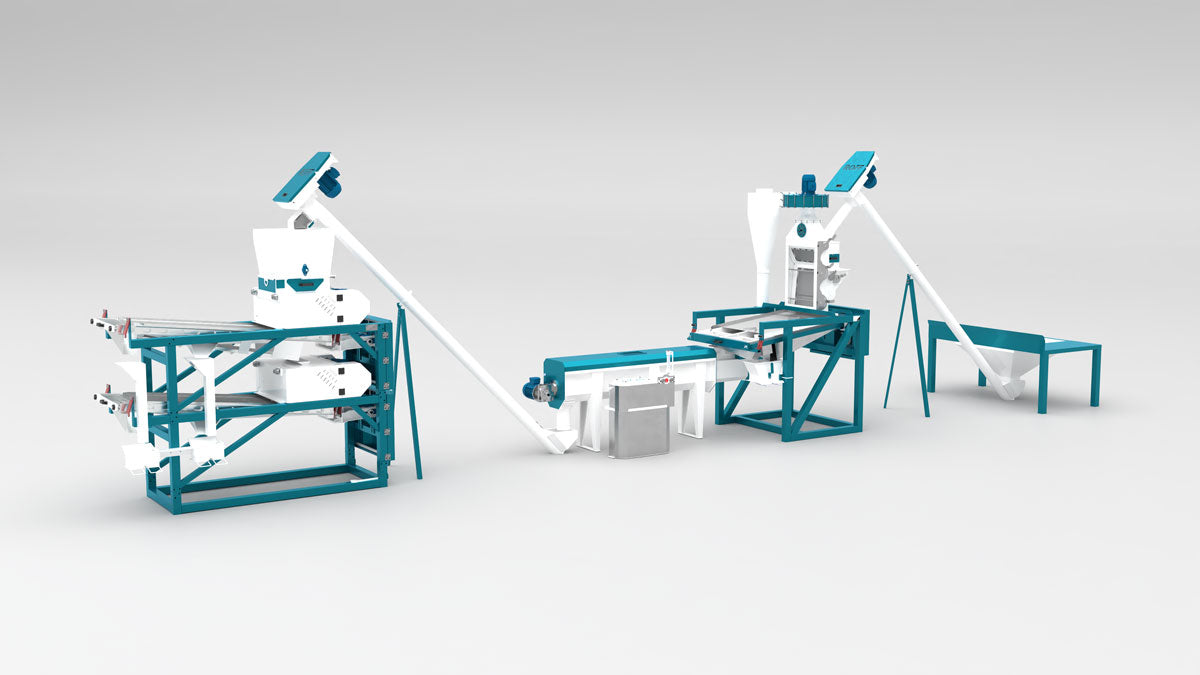

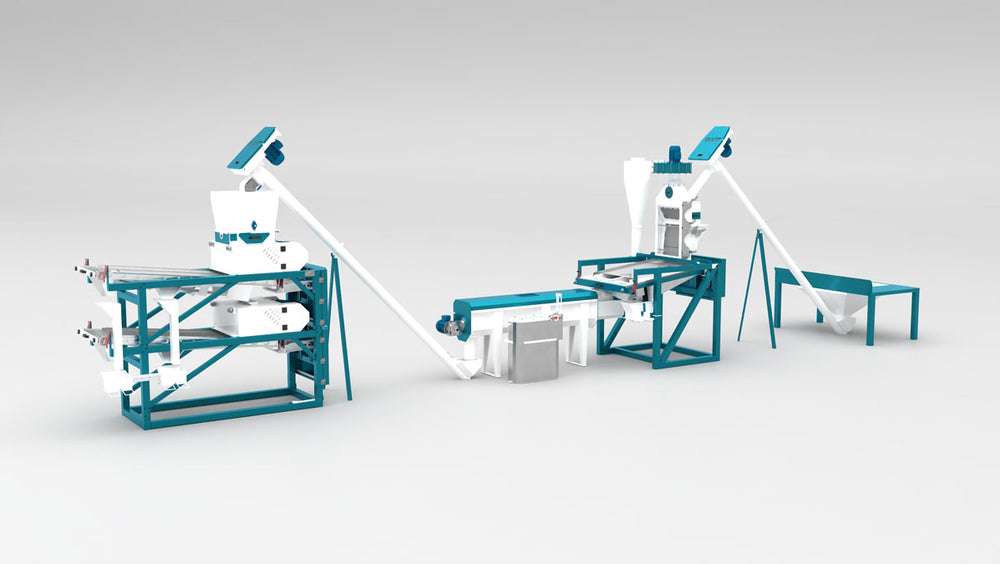

For bulk intake systems:

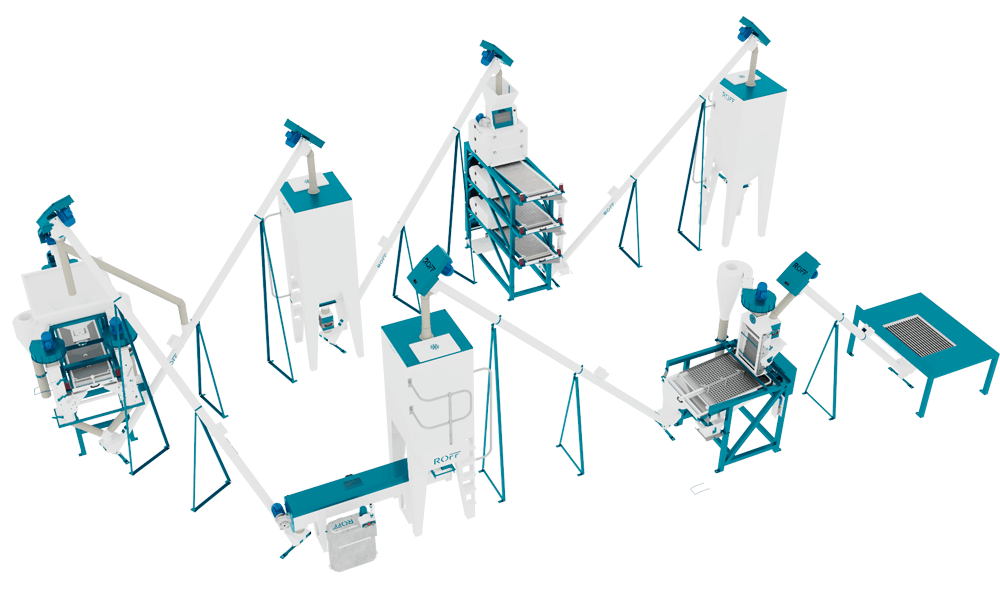

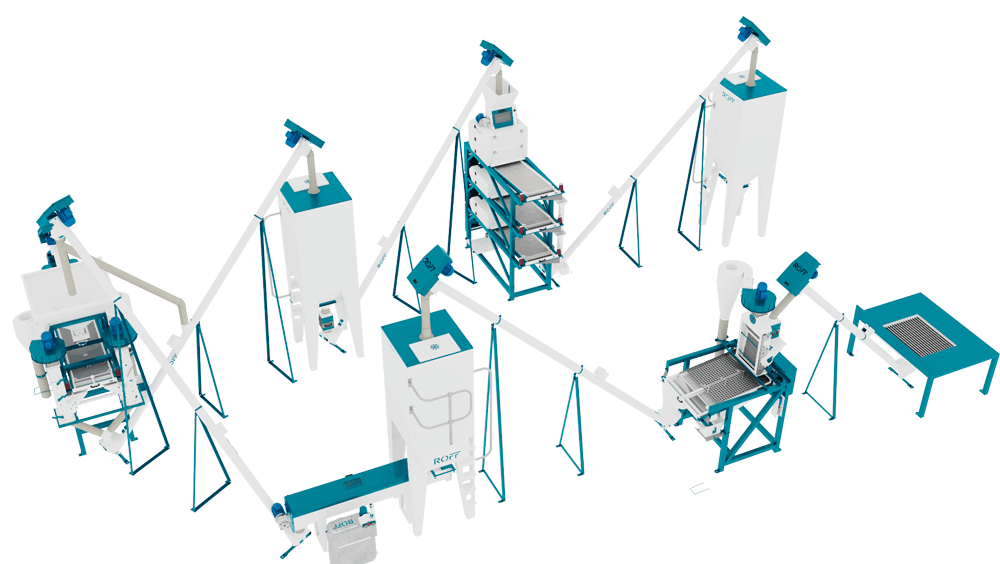

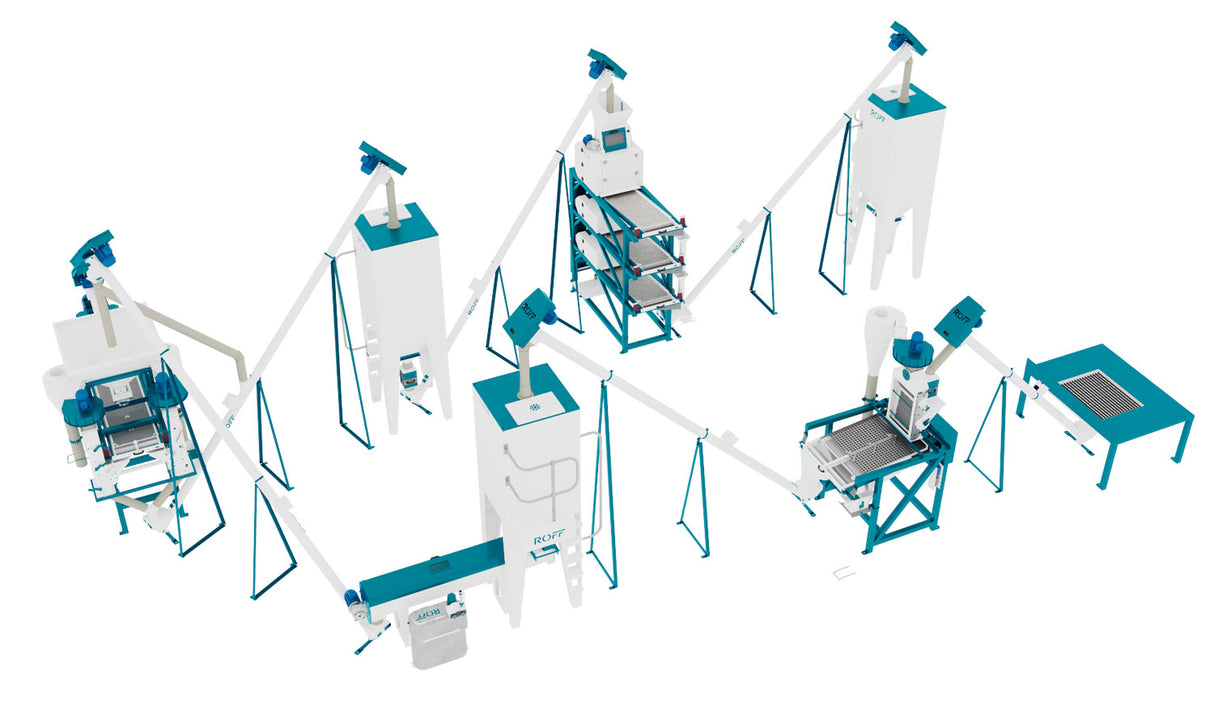

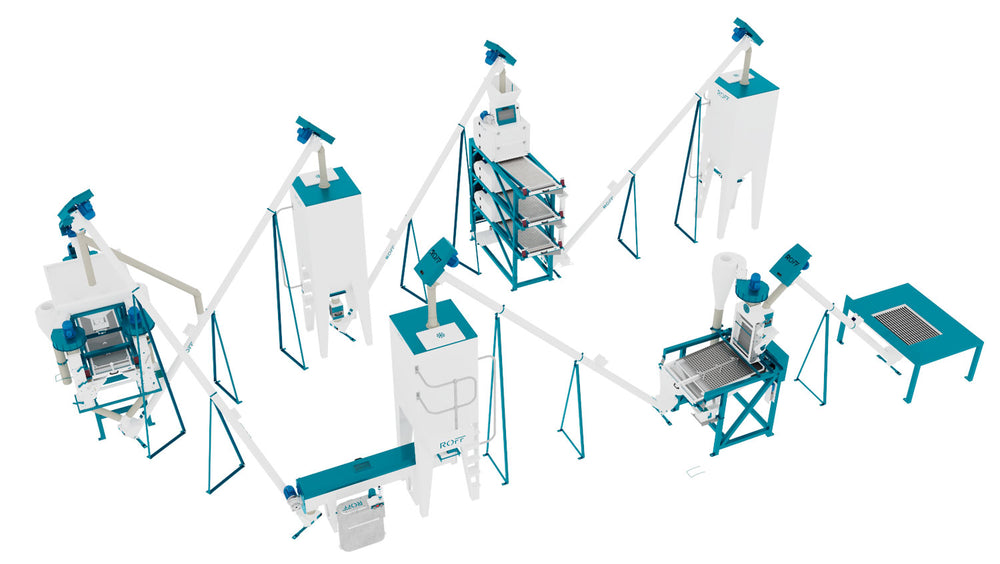

- Roff C-80, R-70 and R-40 Turnkey Mills: Higher capacity milling systems that integrate with bulk handling for streamlined operations.

- Roff Screw Conveyors: Transfer maize from pit to silo or mill efficiently.

- Grain Pre-Cleaners: Improve hygiene and protect milling equipment.

Which intake system is right for you?

Choosing between bulk and bagged maize intake is not just about budget – it’s a strategic decision. Bagged intake may work for low-volume, labour-rich settings, but if you’re looking at consistent quality, higher output, and long-term cost efficiency, bulk intake is the way forward.

At Roff, we understand the African context – whether you’re in rural Zambia or running a growing operation in Gauteng, South Africa. Our expert team can help you plan an intake system that matches your capacity, budget and goals.

Frequently asked questions

What’s the main difference between bulk and bagged maize intake?

Bagged intake relies on manual off-loading and storage of 50 kg–90 kg sacks, while bulk intake uses pits, conveyors and silos to move maize mechanically. The choice affects labour, hygiene, speed and long-term operating cost.

At what throughput does bulk intake become cost-effective?

For most African mills, once you mill about 2 t/h or more, the lower labour bill and reduced spillage of a bulk system usually offset its higher capital cost within three to five years.

Does bulk intake really improve food safety?

Yes. Sealed silos, inline pre-cleaners and aeration cooling block pests, remove foreign matter and stabilise moisture—key steps in a HACCP plan. Bagged grain faces more handling points and higher mould or insect risk.

How much space do I need for a bulk intake system?

Because silos store grain vertically, a bulk setup often uses less ground area than stacking thousands of bags. You will, however, need room for an intake pit, conveyor route and service access.

Can I start with bagged maize and upgrade later?

Absolutely. Many millers launch with Roff’s SP-1 (bagged intake) and later add a pit, auger and silos when volumes grow. Roff’s modular design makes the transition straightforward, and turnkey lines like the R-70 integrate seamlessly with bulk handling.

Ready to scale your milling business?

Speak to a Roff sales consultant today and get informed guidance on choosing the right intake system for your maize mill.

Sources:

https://storedgrain.com.au/dealing-with-high-moisture-grain/

https://www.osha.gov/grain-handling

https://www.researchgate.net/publication/260996752_PICS_bags_for_post-harvest_storage_of_maize_grain_in_West_Africa