Milling businesses across Africa are looking for one thing: reliable performance with lower operating costs.

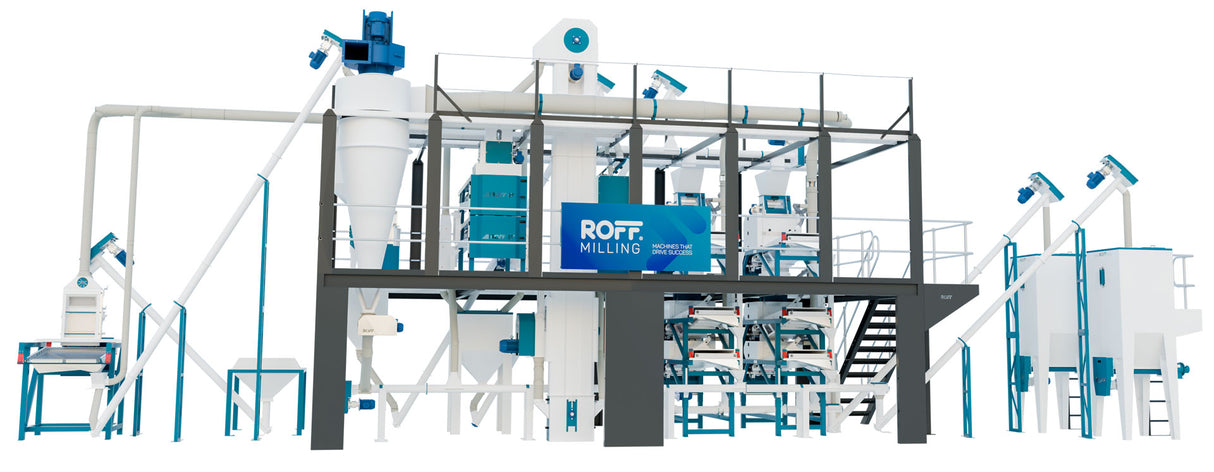

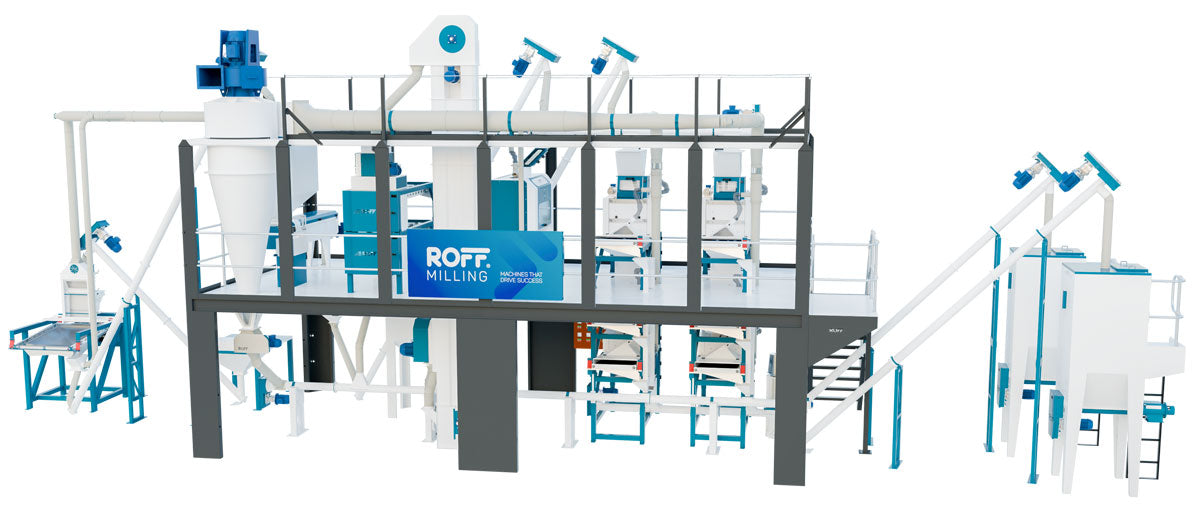

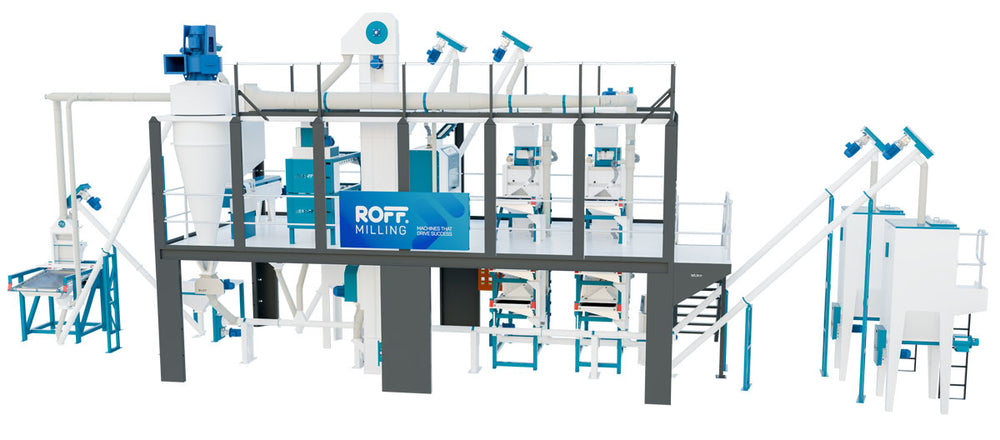

That’s why Roff has launched the next-generation 2026 R-40 maize mill — a compact 2–3 ton per hour turnkey maize milling plant that delivers commercial-grade flour quality and extraction, now in a smaller, more efficient footprint.

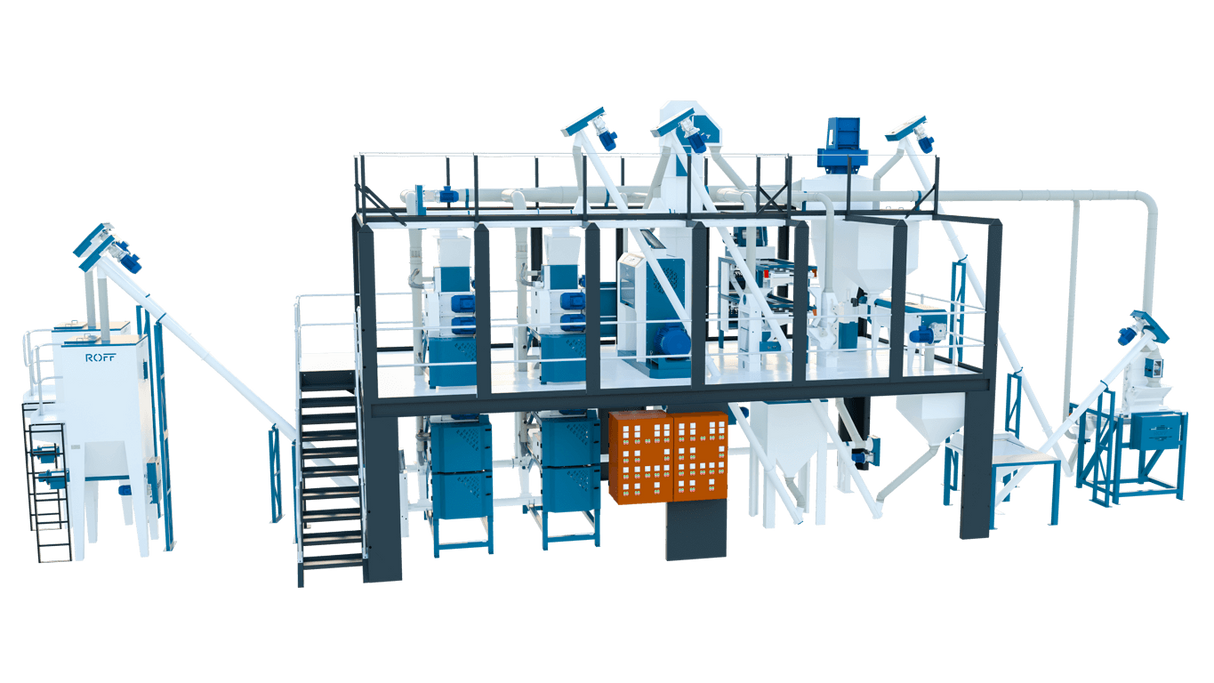

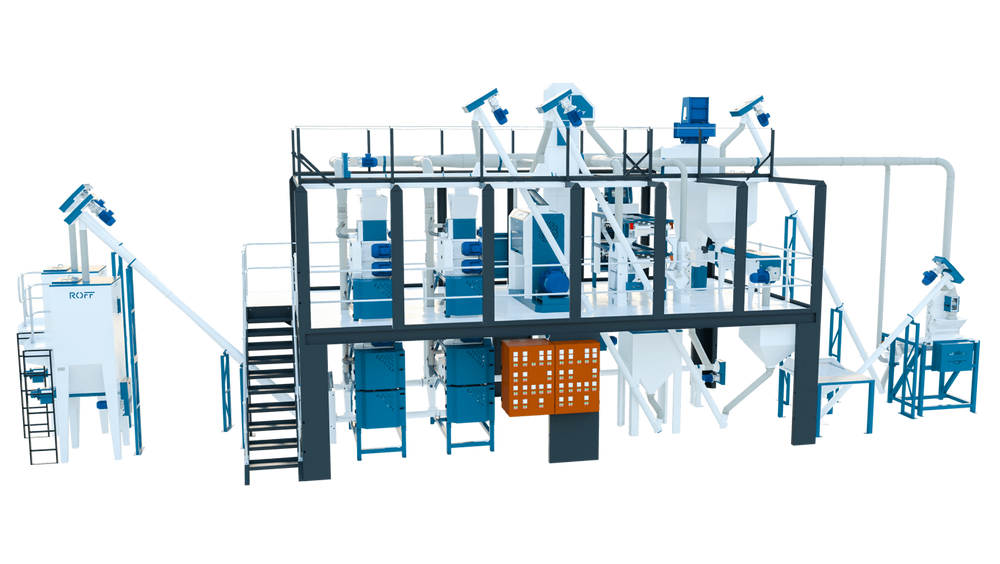

Built on the success of Roff’s flagship R-70 platform, the new R-40 brings proven milling principles to entrepreneurs and millers who want to start strong, expand capacity, or diversify product lines with a modern, future-ready system.

Built on the proven R-70 commercial milling platform

Since its introduction in 2012, the R-70 maize mill has become a benchmark for reliability and profitability in Africa’s maize milling industry. With more than 75 installations across the continent, the R-70 has earned its reputation through robust construction, easy operation, and strong extraction performance.

The first R-40 (launched in 2021) was created by scaling the R-70 design into a compact milling solution — keeping the same high-quality output, but with a smaller throughput and footprint suited to emerging and growing operations.

Now, the 2026 R-40 maize mill continues that lineage, upgraded with Roff’s latest technology improvements and a streamlined layout focused on efficiency.

What’s new in the 2026 R-40 maize mill?

The next-generation R-40 integrates key upgrades originally introduced on the R-70 line, refined into a system that is easier to operate, easier to maintain, and more cost-effective over time.

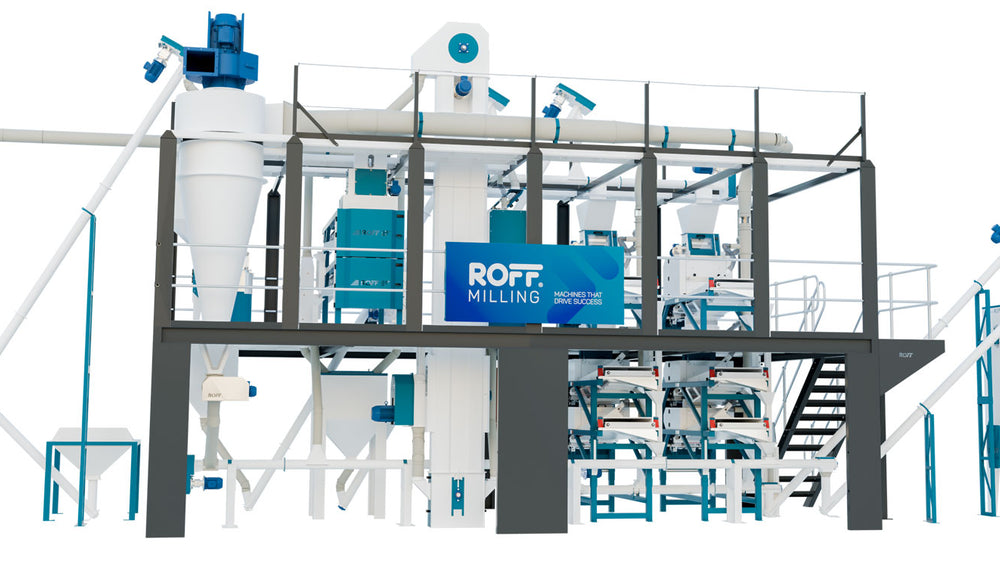

1) 30% smaller footprint

The redesigned plant layout reduces overall space requirements while improving accessibility and maintenance practicality. The gravity-conveying design supports lower energy usage and a cleaner process flow.

2) DGX degerminator now standard

Every 2026 R-40 includes the DGX degerminator as standard. This technology delivers cleaner separation, reduced wear on components, and lower power consumption — improving long-term reliability.

3) VTN vitamin doser for precision fortification

The new VTN vitamin doser provides consistent, accurate micronutrient dosing — supporting compliance and product consistency, batch after batch.

4) Modern dark-grey frame and improved lead time

The new frame design reflects Roff’s industrial identity and innovation drive, while also supporting improved production efficiency and reduced lead times.

Compact maize milling plant with big-mill results

A compact maize milling plant should not mean compromised performance.

By simplifying the process flow and reducing unnecessary moving parts, the next-generation R-40 delivers:

- Lower power consumption

- Reduced maintenance requirements

- Lower running costs

- Reliable, consistent milling performance

Extraction rates designed for profitability

Extraction rates depend on maize quality and regional conditions, but the 2026 R-40 is designed to achieve:

- 69–74% extraction for super maize meal

- 79–84% extraction for special or breakfast meal

This gives millers flexibility to supply the market segment that best fits their pricing, positioning, and local demand.

“We’ve taken everything customers loved… and reimagined it for the future — smarter, leaner…”

Charl Marais

Designed for African milling businesses and entrepreneurs

The R-40 is built for real-world milling conditions — where simplicity, durability, and uptime matter.

This maize milling system is ideal for:

- New entrepreneurs starting a commercial maize milling business

- Existing millers expanding into new regions

- Operations diversifying product offerings with a smaller, high-output mill

The plant can be operated by a small team — typically one operator and three to four packers per shift, with minimal training required.

Turnkey maize milling solution with fast installation

As a turnkey maize milling solution, the R-40 includes all the essential components required for a complete, ready-to-run operation, including:

- Cleaning

- Conditioning

- Degermination

- Milling and grading

- Product bins

- Control panels and wiring

- Training and commissioning support

It also requires minimal civil works and can typically be installed in around one month, depending on site readiness and logistics.

A future-ready maize mill built to drive success

At Roff, we believe milling success comes from simplicity, reliability, and profitability.

The next-generation 2026 R-40 maize mill represents a step forward for growing milling businesses — combining proven commercial performance with a compact footprint, streamlined efficiency, and smart technology upgrades.

Ready to take the next step?

Explore the next-generation R-40 maize mill and see how a compact 2–3 TPH plant can help you start strong, expand faster, and run leaner. Find out more

Want more capacity? Check out the R-70 maize mill

Machines that drive success.