Published on March 12, 2022 • Updated October 8, 2025

Maize milling plays a central role in food security and commercial food production across Africa. Yet the process and terminology used in the maize milling industry can seem technical or confusing to new entrants or entrepreneurs. This blog breaks down the key steps in the maize milling process and explains essential terms in a clear and practical way, helping you better understand how maize becomes maize meal.

The journey of maize: from farm to mill

The journey of maize: from farm to mill

The maize milling process begins well before the maize enters the mill. It starts on commercial or subsistence farms, where maize is grown, harvested, and typically transported to storage facilities like silos complexes or bulk bag storage warehouses. Here, it’s graded and dried if the moisture content is too high, before being sold and transported to the millers.

This means that maize quality, moisture and the amount of impurities can differ widely from one load to the next, and between suppliers.

Step-by-step maize milling process

1. Intake and pre-cleaning

Maize arrives at the mill by road or rail in bulk or bags from grain traders, or directly from the farm. Weighbridges or intake scales record the mass. Once in storage and before milling, the miller test and grade the maize for moisture content, kernel quality, and foreign matter like stones, husks and dust. Quality control at this early stage ensures that only suitable maize enters the milling process.

Maize arrives at the mill by road or rail in bulk or bags from grain traders, or directly from the farm. Weighbridges or intake scales record the mass. Once in storage and before milling, the miller test and grade the maize for moisture content, kernel quality, and foreign matter like stones, husks and dust. Quality control at this early stage ensures that only suitable maize enters the milling process.

Large commercial operations with silo storage will use a pre-cleaner before intake, like the Roff CLR 107 with a pre-cleaning capacity of up to 18 ton/hour. If bag storage is used, the maize is pre-cleaned before being conveyed to the mill using either screw conveyors, conveyor belts or bucket elevators. View Roff’s range of cleaners.

This maize is still considered “dirty” and needs fine cleaning to remove dust, breakages and impurities that were either introduced during storage, conveying or slipped past the pre-cleaner. A cleaner with fine-cleaning screens is used, most effectively in combination with magnets and aspirators.

For more on the importance of proper storage, read our blog on effective grain storage. This stage ensures grain quality and protects downstream equipment.

Even at community mills, clean maize is essential and it can be done by hand using the bucket and wind method, or Roff’s simple table screen.

2. Conditioning (damping)

Conditioning is the addition of water to get the germ and bran moist for optimal separation, allowing it to rest for a set amount of time. This softens the bran and toughens the germ and endosperm, improving separation and extraction efficiency during milling. Controlled humidity also increases the effectiveness of degermination and improves maize meal quality. Conditioning combined with a degerminator gives the best results, but for markets where maize is not degerminated, the conditioning step drastically improves the bran separation during milling.

In community mills, conditioning this can be done by hand or using Roff’s Posho mixer.

3. Degermination

The maize kernel consists of three parts: the bran, germ and endosperm. Degermination removes the germ and some of the bran from the endosperm, which contain most of the fibre and oil, to achieve a more refined maize meal and to prolong the end product’s shelf life. The by-product can be used as an ingredient in animal feed, further adding to profitability.

Some regions do not include the degermination step, but go straight to milling after conditioning, especially when producing special maize meal.

You can read more about the history of degerminators here.

4. Milling and sifting

4. Milling and sifting

The endosperm is ground using roller and sifted into various particle sizes. Some markets require an even finer maize meal, so a hammer mill is used in combination with roller mills. Explore Roff’s range of maize milling equipment to find the right solution for your operation. Common maize milling products include:

- Highly Refined, or Super maize meal (fine, white, high extraction)

- Refined, or Special maize meal (less refined, undegerminated)

- Samp (larger particles used for cooking)

- Grits (used for breakfast cereals, snacks and brewing)

- Bran (a by-product used in animal feed)

If you would like more info on the different grades of maize meal in Africa, read this blog.

5. Fortification (optional but regulated)

Fortification mixes containing essential vitamins and minerals like iron, zinc, and folate can be added to the maize meal. This is often a legal requirement in many African countries to combat nutrient deficiencies. The Roff Micro Doser Feeder is ideal for feeding small capacity dry products such as vitamins into maize meal. Learn more about fortification and its role in public health.

6. Packaging and storage

The final product is weighed, packed, labelled, and stored in hygienic conditions ready for wholesale or retail distribution. Packaging can either take place manually, or via a semi-automatic or automatic process. Apart from the operational aspects involved in packaging your product you also need to consider how your product packaging looks. We have some handy packaging design tips here.

Find the maize mill perfect for your needs

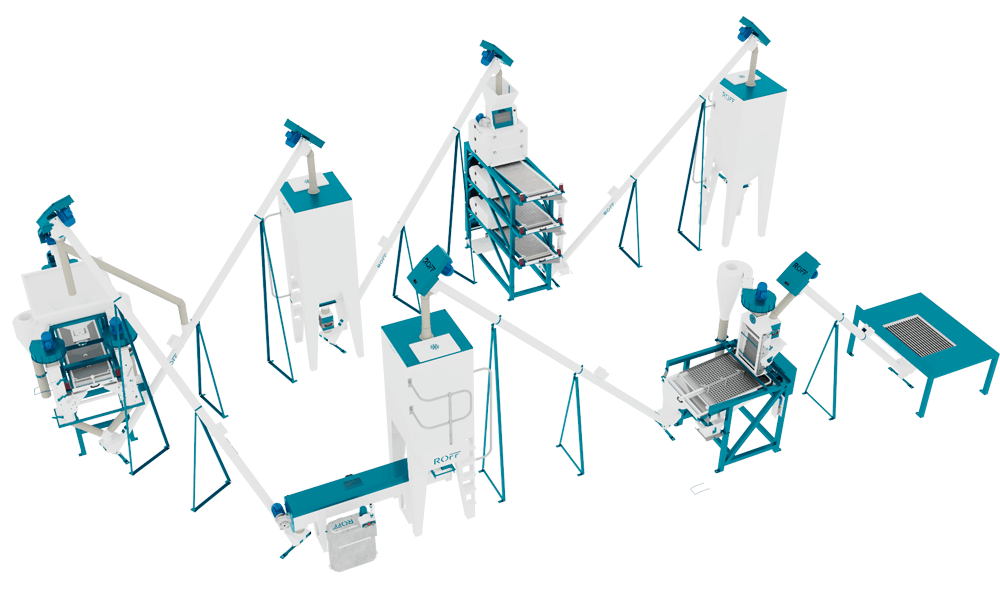

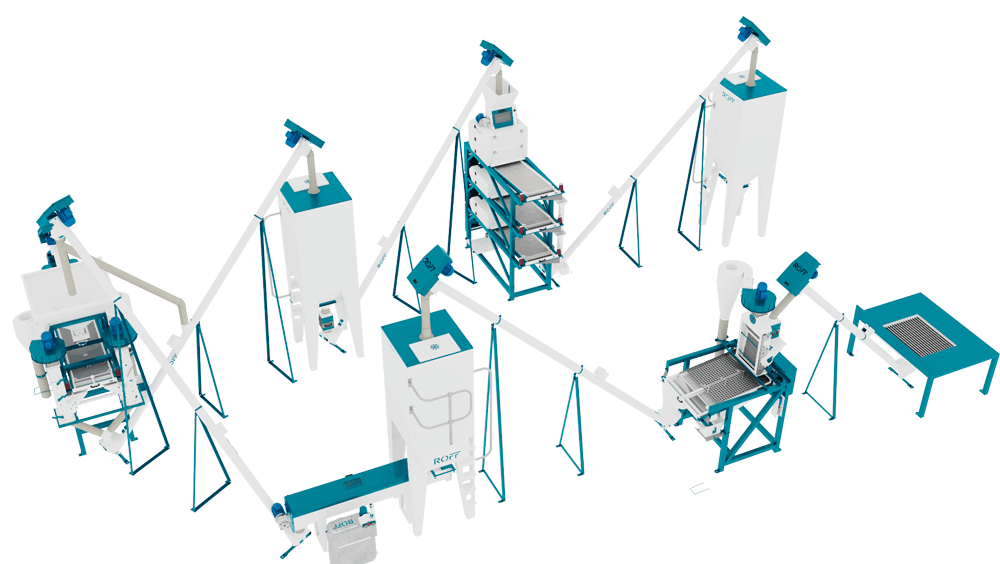

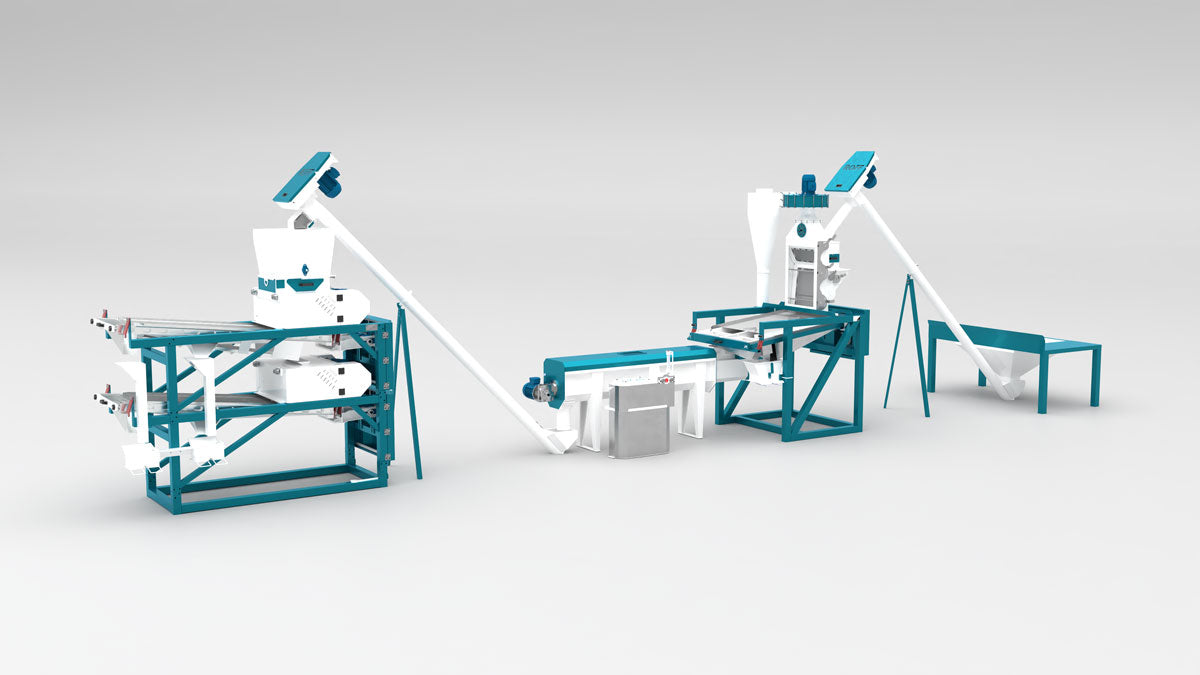

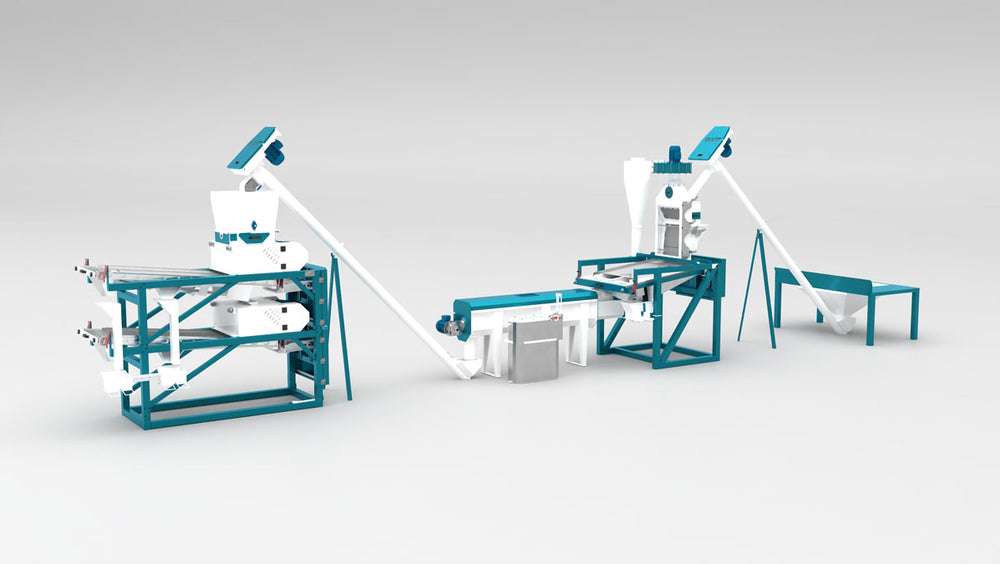

Roff offers a host of maize mills to cater for your every milling requirement, whether you’re just getting started, or are looking to upgrade your operation. In this section we look at some of the options in the Roff range of turnkey maize mills. Let's start with a small commercial mill, the Roff SP-1 650 kg - 1 ton maize mill.

The Roff SP-1 is an example of a small compact mill, and is perfect for starting your maize milling business.

Roff’s SP-1 mill is everything you need to start milling high-quality maize meal and/or produce stock feed and from arrival at your site, it can take as little as two weeks to set up. We simplified the milling process to its core stages:

Step 1: Cleaning

Step 2: Conditioning

Step 3: Degermination

Step 4: Milling

This makes it possible to produce high-quality maize meal without a massive upfront investment. Roff offers a range of optional extras that improve capacity and quality and can be added quickly and conveniently as the need arises.

All you need to supply in order to operate your Roff SP-1 maize mill is a building, a water point, a forklift for installation, and electrical installation. If you are looking to go smaller, it's well worth reading our article on the differences between commercial and community milling. Also have a look at the Roff Posho mill, specifically designed for rural productivity.

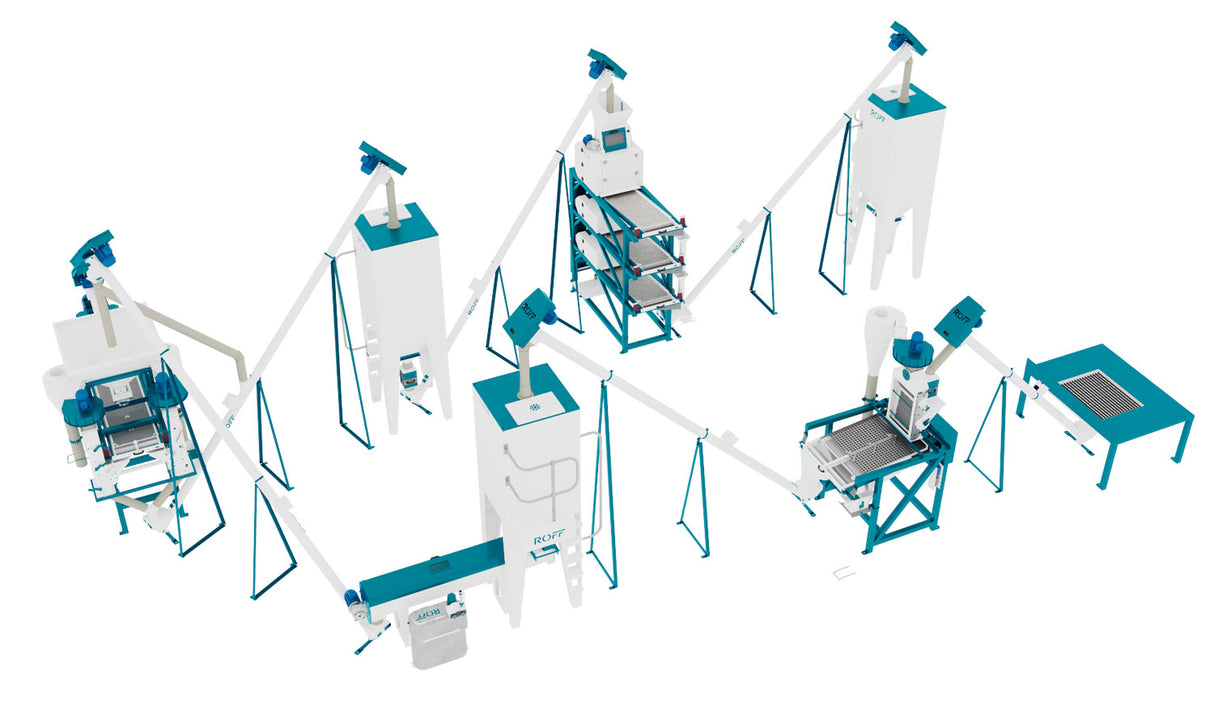

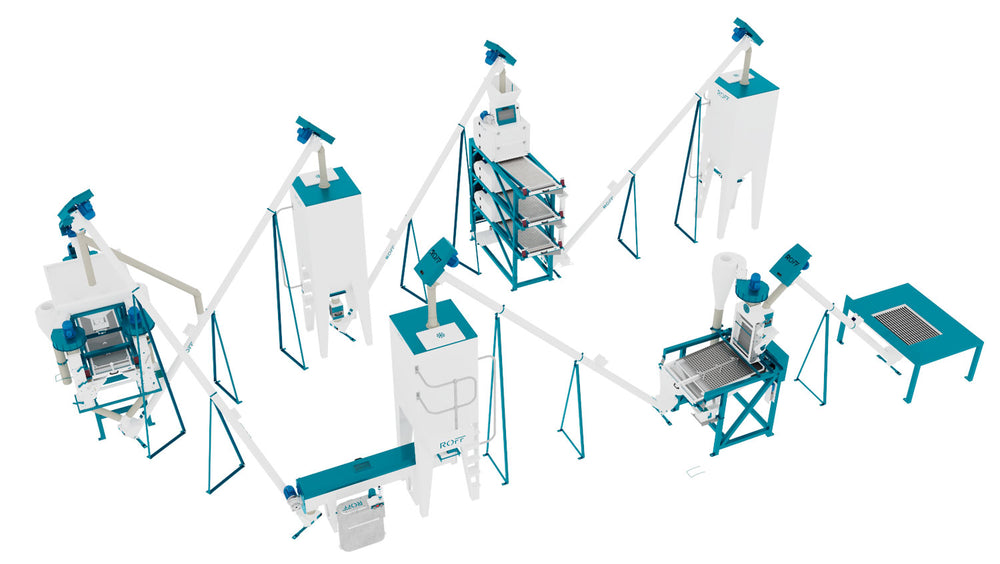

Do you need larger capacity?

If you are ready to produce on a larger scale you may want to consider the Roff R-40 maize mill. It's next in line size wise and the newest in the range, producing 2 - 3 tons per hour or 50 - 70 tons per day.

The R-40 is built on proven equipment (MK-6 platform) and boasts Roff's best-in-class extraction rates. It's compact with a footprint of only 15m(L) x 9m(W) x 6.6m(H).

To view the rest of Roff range of turnkey maize mills, you can go here.

At what capacity does maize milling become profitable?

One way we support entrepreneurs is by advising them on how to develop a solid business plan. And part of that is determining how you are going to be profitable. So, we developed a free profit calculator you can use to crunch all the numbers to calculate your success. Try it out. You won’t be sorry you did.

Common maize milling terms explained

- Bran: The outer layer of the maize kernel, high in fibre.

- Germ: The part of the kernel that can sprout into a new plant; rich in oil and nutrients.

- Endosperm: The starchy core of the maize kernel, used to make meal and grits.

- Degermination: The process of removing the bran and germ.

- Extraction rate: The percentage of usable product (typically maize meal) extracted from a given quantity of raw maize.

- Grist: The blend of maize used in milling to ensure consistent quality and performance.

- Sifting: Separating the ground maize into different sizes and textures.

- Fortification: Adding nutrients to maize meal to improve public health.

- Mass determination: Measuring the quantity of maize received or milled for traceability and control.

Why consistency matters in maize milling

A key challenge in commercial maize milling is maintaining a consistent, high-quality product. Because maize quality can vary by source, region, or season, professional millers often blend different batches to produce a uniform grist. This ensures that customers get the same quality product every time, which is especially important for food brands, retailers, and institutional buyers.

Consistent maize meal not only meets customer expectations but also ensures compliance with food safety regulations and fortification standards.

Conclusion: understanding the maize milling process

Understanding the maize milling process and key terms helps both aspiring millers and informed buyers make better decisions. Whether you're starting a maize milling business or looking to improve your current operations, check out our guide on how to start a maize milling business, knowing how the maize kernel is transformed into a range of maize meal products is the first step to success.

For start-up millers, small-scale operators, or large commercial facilities, mastering these basics gives you a strong foundation in delivering quality, compliant, and profitable maize meal.

References

SAGMA Maize Module 1: Introduction to maize milling (National Chamber of Milling, 2017)

SAGMA Maize Module 2: Maize intake and safe storage of grain (National Chamber of Milling, 2017)

11 comments

Q1: does SP-1 mill come with a semi-automated packing optional feature? If not, please clarify?

Q2: If a client is interested, do you charge for site inspection of their factory area or you do it for free?

Q3: when a client (from foreign country) has completed payment, do you charge delivery of the equipments & installation? Or is the delivery & installation for free?

———

Roff Milling replied:

Hello, Q1. Semi-auto bagging equipment is an optional extra and can be added. Not usually recommended on SP-1 due to lower volumes not always justifying it. Q2. Site visits depend on a few things, Most cases layout of mill can be done by just receiving dimensions of warehouse. Q3. Delivery and installation is quoted. If you require any further assistance, please do not hesitate to contact us.

How do you calculate shelf life for the maize products? Thank you

———

Roff Milling replied:

Hi Tatenda, we wrote a blog article about that – read it here – https://www.roff.co.za/blogs/blog/how-to-calculate-and-extend-the-shelf-life-of-maize-meal

How much is the smallest commercial maize meal and l m in Zimbabwe. Is there any guarantee as to your machinery.

———

Roff Milling replied:

Hello Rudd, please forward your inquiry to our dedicated sales team at sales@roff.co.za<mailto:sales@roff.co.za> for them to get in touch. Regards

How much is a small commercial maize meal production machine

———

Roff Milling replied:

Hello Kenias, our sales team will get in touch soon. Regards

Hi,

I would like to set-up a corn milling facility in a small island in Tawi-Tawi Province, Philippines.

Do you have a representative in the Philippines?

Hope to receive your reply.

Thanks.

———

Roff Milling replied:

Good Day, our sales team will get in touch soon.

How much is the whole setup, am in Malawi. Do you offer it on a loan ? I really need this machine

———

Roff Milling replied:

Hello Owen, our sales team will get in touch soon.

We want to start maize processing business here in Nigeria, but we lack experience. How many kg can produced 50kg of maize flour?And what type of your machine can we used?

———

Roff Milling replied:

Hello Ahmed, our sales team will get in touch. Regards

———

Roff Milling replied:

Good Day, please have a look in your e-mail inbox, our sales team has been in touch. Regards

20tons per day machine is how much

———

Roff Milling replied:

Hello, our sales team will get in touch shortly to assist.

I want to start a business to sell maize meal hence I want to purchase the smallest processing plant.

I want to start up the maize milling process in Bhutan. How do I start? I need experts to help me

———

Roff Milling replied:

Hello Nima, one of our consultants will get in touch shortly.

Maize mill process

———

Roff Milling replied:

Hello Sam, thank you for your message. Please send us a mail to sales@roff.co.za<mailto:sales@roff.co.za> with all your questions, and our skilled consultants will get in touch. Kind Regards