There are many factors that play a part in producing a quality product for the discerning maize meal market in South Africa and the rest of Africa. One such factor is the influence of grain hardness.

It is well known that maize meal production results in a substantial amount of by-product, which in part can be attributed to the hardness or softness of the maize cultivar. For maize meal producers, both on a large and small scale, this waste can be costly. By understanding the influence of maize hardness and selecting the correct maize cultivar, producers can increase their yields and cost effectiveness.

Wiana Louw, General Manager at The Southern African Grain Laboratory, explains the importance of grain hardness in maize meal production.

Q: WHY IS THE HARDNESS OF THE MAIZE KERNEL IMPORTANT FOR THE QUALITY OF MAIZE MEAL PRODUCTION?

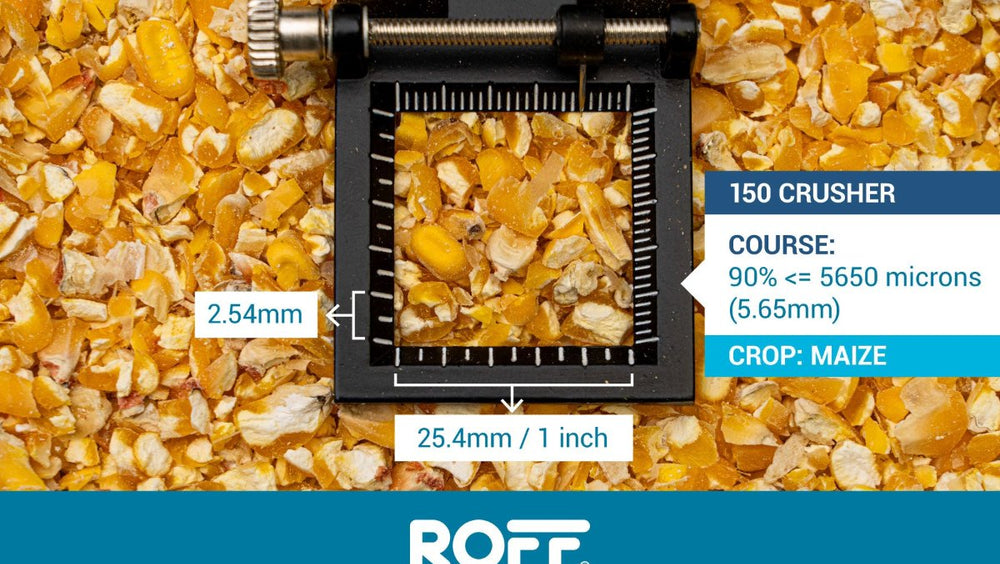

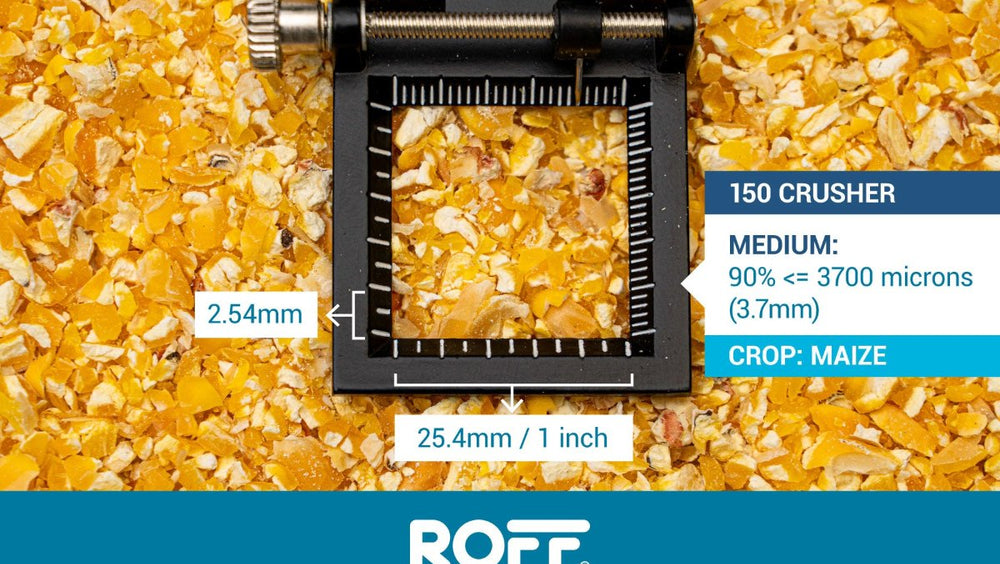

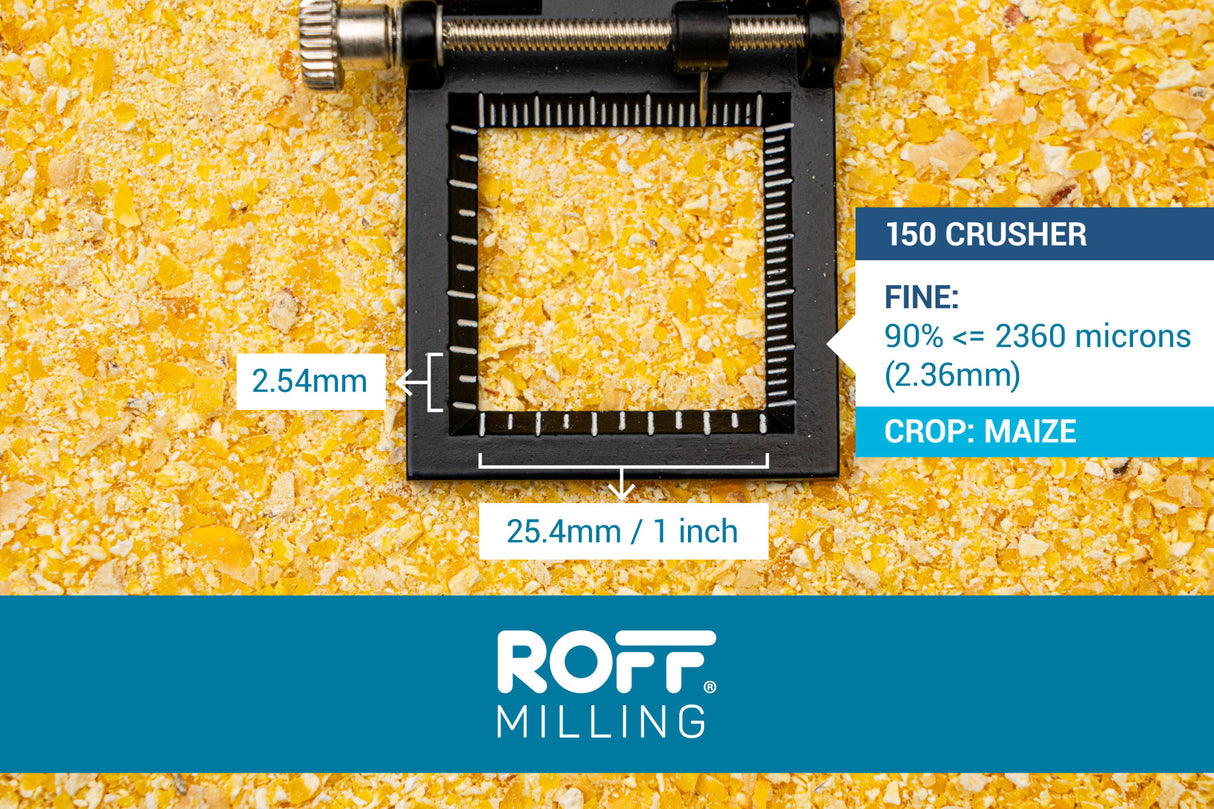

A: The hardness of maize is determined by the genetic make-up of a specific cultivar of maize. It is used as a parameter to describe the resistance of maize against being crushed in a mill, typically between the two rollers of a roller mill. Very soft maize will break into a fine powder of starch-like particles during the degermination process, where it ends up in the chop and is very hard to recover. Hard maize on the other hand will produce a mixture of fractions, namely a small fraction of powdery starch, and a variety of fractions consisting of grit-like particles that are resistant to shatter.

A typical example of grits from hard maize is the familiar samp or maize rice products. It is very difficult during milling to sieve out impurities from a soft maize cultivar after it has been shattered. The hard maize grits are easy to clean, and the objective of the milling process is to produce grits with as low as possible levels of residual oil and fibre (ash). Oil will reduce the shelf-life of the product due to rancidity, while high ash contents will produce flours that look “dirty” with a grey colour that also shows up in cooked maize porridge.

Find out more about maize meal quality checks in our four-part blog series, covering moisture content, speck count, granulation and oil checks.

Q: WHAT DETERMINES MAIZE HARDNESS?

A: Before maize meal production, the maize hardness is determined genetically by regulating the expression of the type and amounts of protein and starch in maize during the growing phase. The structural proteins are called Prolamins of which the chemical structures of various subunits are known. The ratio and quantity of these subunits in the maize determine the hardness of the maize. During development of the maize kernels in the field, the protein forms a matrix in which starch is embedded. If the matrix is strong, the resulting end structure will be hard. The system can be compared to that of a wall built with bricks. If the wall is built with strong cement and optimal ratios of cement and bricks, the wall will be exceptionally strong.

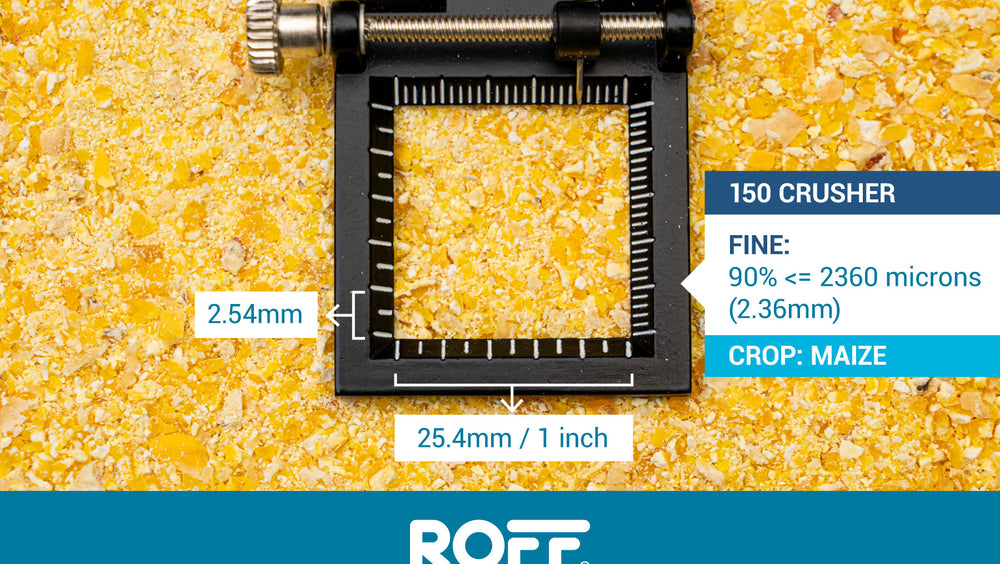

ROFF's range of mills and crushers are specifically designed to effectively crush hard maize during maize meal production and achieve the highest quality end product. The quality of this maize meal ensures that the meal meets the high standards of the South African market, which increases it’s marketability and cost effectiveness for the producer.

1 comment

Am interested in starting a low budget community mill here in Kenya. Kindly share information for a successful venture.

———

Roff Milling replied:

Hello Steve, our sales team will get in touch soon. Kind Regards