When there’s a downturn in the market and profits are under pressure, millers’ first reaction might be to cut on maintenance costs in the mill. But this reduction in expenses, if approached wrongly, can turn out to cost the shareholders of the company dearly.

The miller’s focus should be obtaining optimal extraction rates the market will allow. Just a 2% improvement in extraction rates, or not losing good product to the chop bag, can make a huge difference to the bottom line of the company. It can mean the difference between profit and loss.

The quality of the products, as well as the technical results of the mill, must be maintained. Here’s how:

01. MAIZE QUALITY

When faced with cost cutting, some millers purchase a lower quality of maize. Instead of WM1, they switch to WM2 and WM3 grades. They hope to achieve the same quality of the finished product with only a marginally lower extraction rate.

Using a blend (grist) of WM1, WM2 and WM3 maize might be an option, but the blend must be carefully selected and monitored to not negatively impact on the quality of the finished products.

An extract from the Maize Grading table below shows the three main deviations which could have a negative effect on the product quality:

| Deviation | WM1 (Maximum %) | WM2 | WM3 |

| Defective maize kernels | 7% | 13% | 30% |

| Maize of another colour | 3% | 6% |

10% |

| Total % deviations (Including foreign matter) | 8% | 16% | 30% |

As illustrated, the percentages of the deviations between each of the grades are large and the lower the grade of maize, the lower is the extraction rate at the mill.

A blend of 70% WM1 and 30% WM2 would be far better than one of 30% WM1 and 70% WM2.

Buying good quality maize and maintaining the best possible extraction through good management in the mill is normally the most profitable method of milling.

02. EXTRACTIONS

It’s the miller’s responsibility to ensure that the required extraction rate is achieved and maintained. This also applies to the milling gain. When there’s pressure on management to be profitable, achieving good technical results is of paramount importance.

The inclusion of lower grade WM2 or WM3 maize in the blend (grist) makes this harder to achieve. Regardless, the miller must keep the mill running to its full capacity and at the planned extraction level.

The following needs regular attention:

Cleaning and conditioning of maize

- Purchase dry maize so that the miller can add maximum moisture to the process.

- Ensure that good maize isn’t lost to screenings by overtailing the top sieve deck of the separator or a holed sand sieve. Check that the machine is operating optimally.

- Check aspirators to see that good maize is not being lifted; also ensure that all of the impurities are separated out of the maize.

- Check that the correct amount of water is added to the maize during first conditioning, and that the moisture of the maize on the mill is correct.

- The second dampening stage before degermination is crucial, as incorrect conditioning at this stage will have an adverse effect throughout the milling process.

- All of the above require extra attention if there’s a percentage of lower grade maize in the feed to the mill.

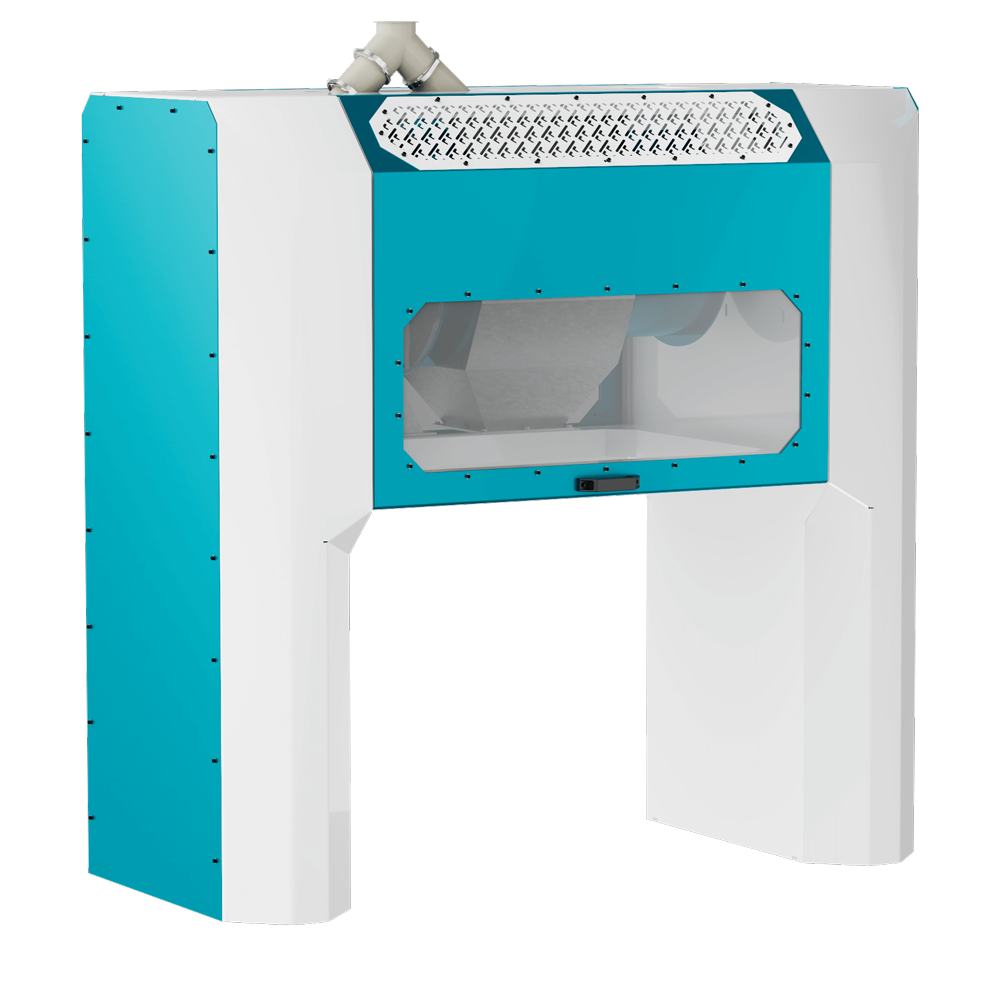

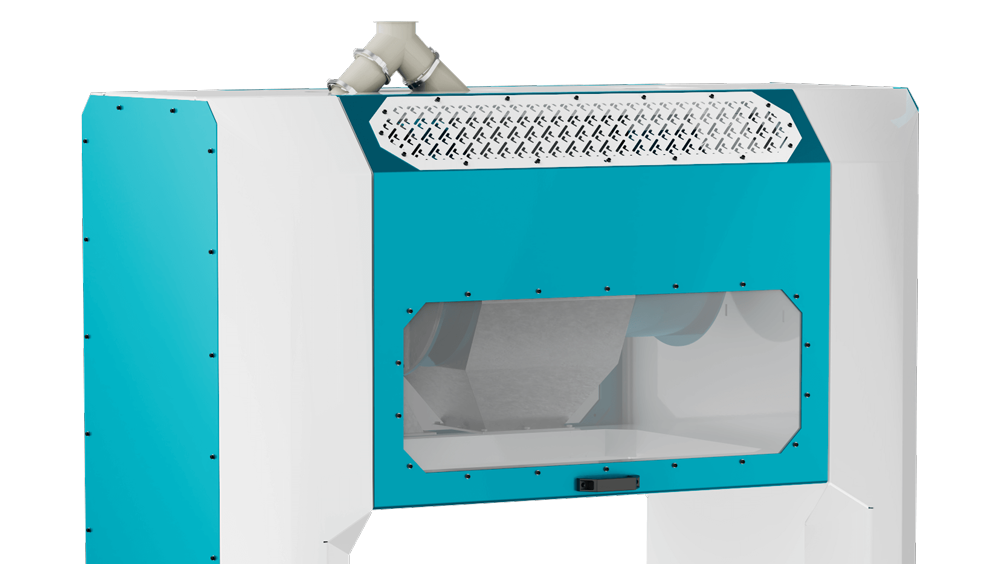

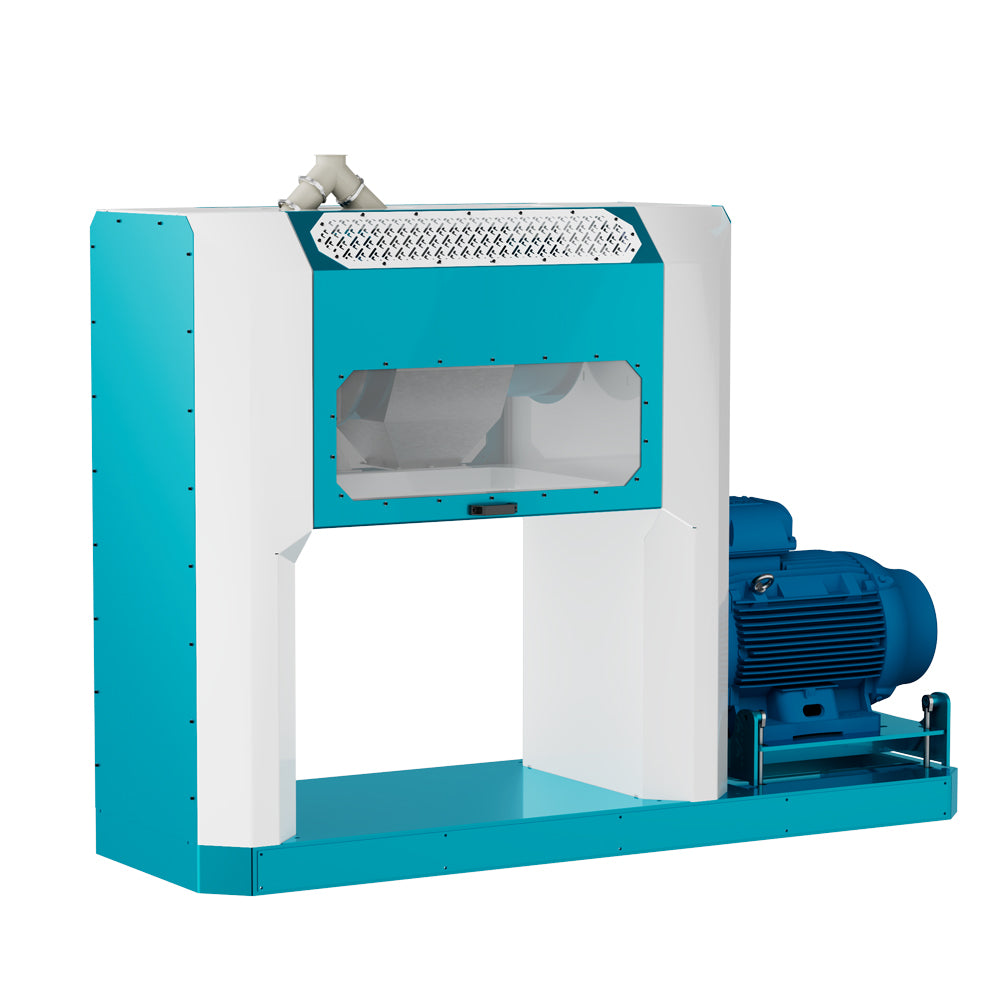

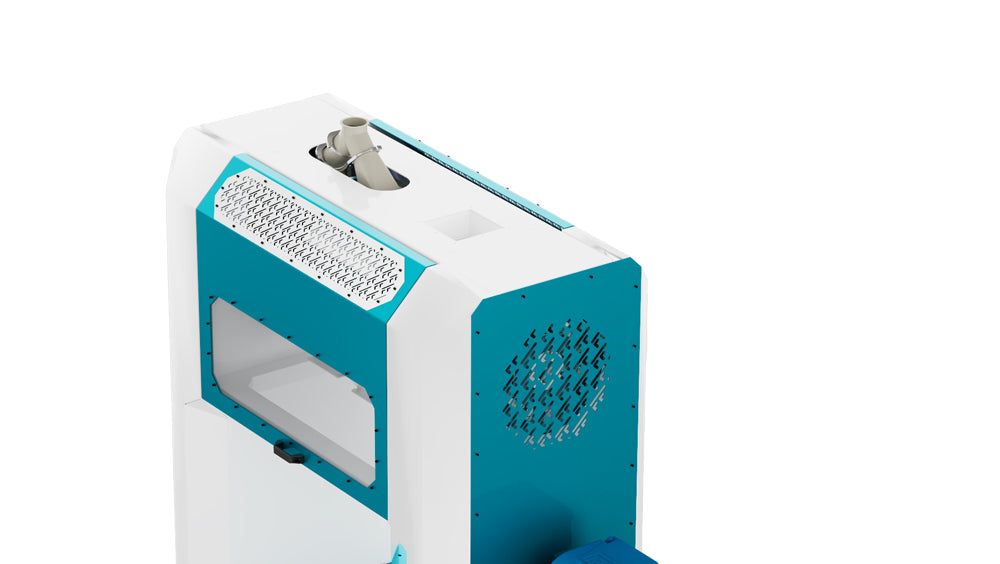

Degerminators

Degerminators require a fair amount of attention from the miller if they are to produce the required results. Some of the more important checks on the degerminator include:

- Ensure that the maize is conditioned properly before degermination. If the maize is too dry, it will break up more readily and cause fines to be lost through the screen, and the overtails will still have a lot of germ/ bran attached.

- The feed to the machine must be set at optimal; too little feed will cause too much breakage of the endosperm.

- The gap between the rotor and casing must be properly set.

- Check that there are no holes in the screen through which valuable endosperm could be lost to offal.

- If a blend of lower grade maize is used, the above becomes even more critical.

Roller mills

The proper setting up of these machines is critical if the extraction rate is to be achieved. Here are just a few items that require attention:

- Check that the feed to each roller mill is correct and properly spread across the full width of the rolls.

- Ensure that the roll is grinding correctly; overgrinding will cause specks in the meal while under grinding will affect the mill balance and cause a loss in extraction.

- Any blunt rolls (flutes worn down) must be replaced as soon as possible.

- Keep the maintenance on these machines up to date.

Aspirators

- Check that the feed to the machines contains the correct stock.

- Check that the machine is set up correctly.

- Check that no good endosperm is being lifted out to offal.

Plan- and monosifters

Plansifters generally receive very little attention when running, but these points are important:

- Do regular checks by drawing samples from each outlet; in this way, possible faults can be quickly fixed. These could include:

- Holes in sieves.

- Blinded sieves.

- Bare dressing of the stock which could cause specks in the meal.

- Rich dressings of stock which could cause the loss of good endosperm to offal.

- Do regular maintenance on the plansifter to minimise issues.

- The senior miller must check the flows and screens in the sifters at least twice a year to ensure that covers haven’t been switched around during normal cleaning of junior staff.

These are just a few points that would require the miller’s attention in order that the extraction, feed rate and milling gain are maintained.

03. QUALITY CONTROL

The frequency of some of the tests outlined under quality could be increased; for example, the speck count test should be conducted hourly. Examination of the chop (offal) is also important as it will indicate whether too much endosperm is being lost.

One quality aspect that’s not always checked is the appearance of the product once packed. Paper bags that are not properly sealed, or are limp in appearance, could cause the customer to choose a competitor’s product which might look neater.

04. MAINTENANCE

During the Great Depression of the early 1930’s, many mills did not lay off key personnel, but used them to do a thorough maintenance programme in the mill instead.

Contact Roff today on +27 56 212 2697, send an email to sales@roff.co.za or visit our website roff.co.za for machines that drive success and valuable milling advice.