Buffalo Millers in Eldoret, Kenya is the culmination of the hard work, dedication and savvy business instincts of Evans Killy, who has built his maize milling business into one of Kenya's most successful brands. Roff Milling has been a partner in this growth journey since the very beginning, and we are proud to share Buffalo Millers' success story with you. A story that now includes two Roff R-70 Maize Mills.

Watch the latest inspiring video:

Humble beginnings

Evans was introduced to agriculture as a young boy. His father, a mechanic by trade, made a career shift into farming, initially renting land from surrounding areas. In 1996, the family bought their own farm in the Soy district, Kenya, where Buffalo Millers is based today. Evans and his brothers grew up as farm kids, watching and learning along the way. When Evans noticed how his father struggled to get fair prices for his produce, the idea of setting up their own maize mill started taking shape.

Gap in the market

After obtaining a degree in Mechanical and Plant Engineering, and completing his post graduate studies, Evans searched for potential suppliers to get him started in maize milling. He came across Roff Milling's website and contacted the team in South Africa. A Roff representative visited the Killy farm to ascertain Evans’s milling requirements. Working within budget, Roff designed a small maize mill to kick-start the business. With four employees, a pick-up truck and a mill with an output of 800kg per hour, Evans set up operations in his father’s old workshop.

Growing from strength to strength

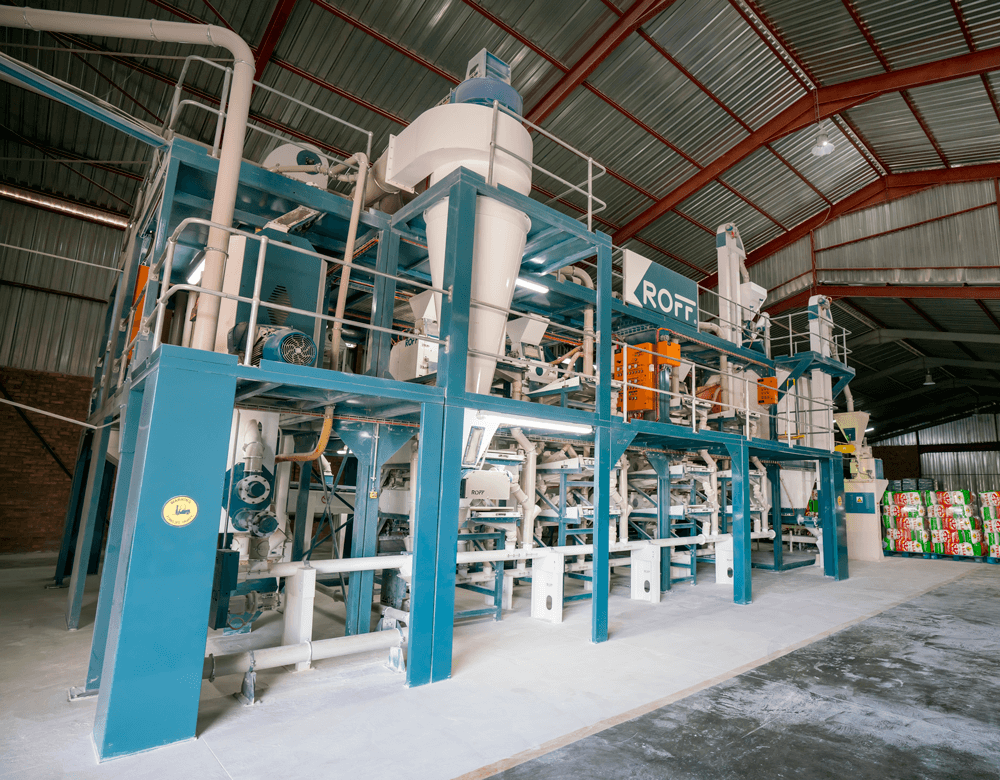

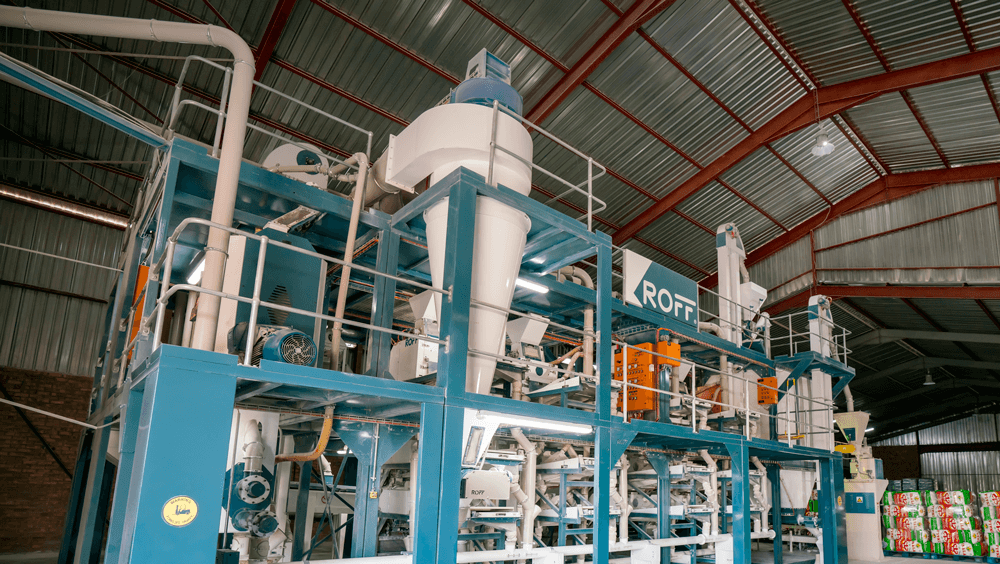

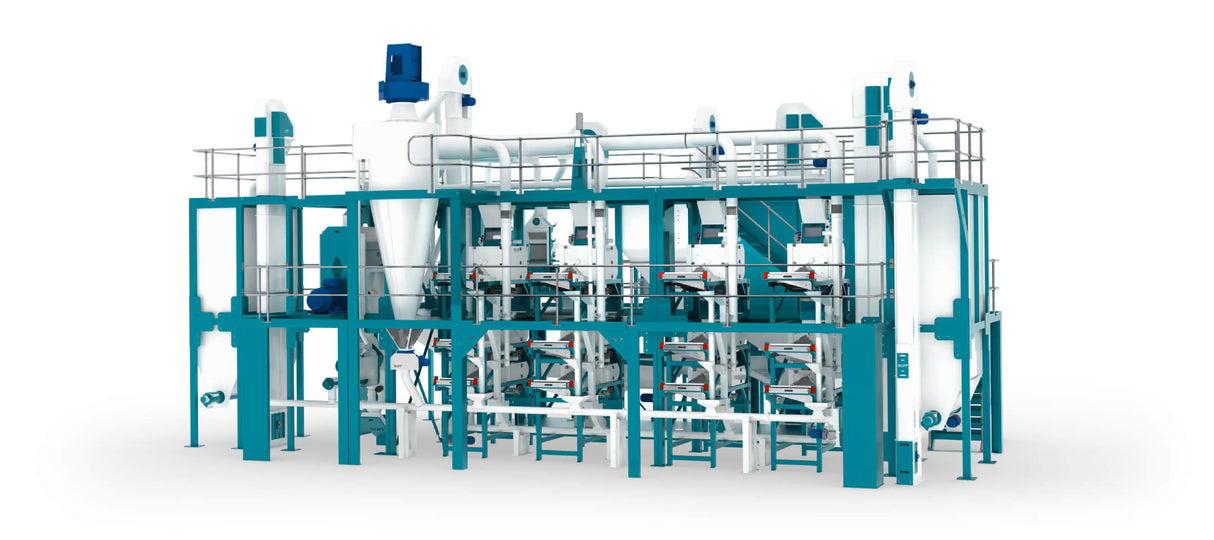

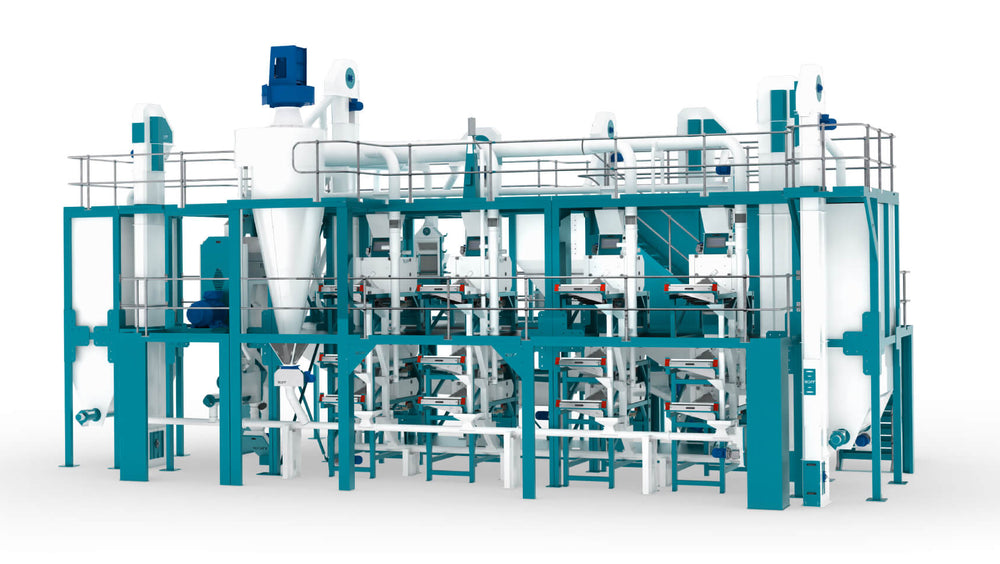

By 2018, Evans was able to invest in his first Roff R-70 Turnkey Maize Mill, which was housed in a purpose-built structure on the farm. The R-70 dramatically increased the business's milling capacity to 100 tons of maize per day, and really gave Buffalo Millers a competitive edge in the market.

Their top-quality maize meal brand, Ufalme, was quickly regarded as amongst the finest in Kenya and came to be enjoyed by Kenyans from all walks of life.

But Evans and his team didn't stop there, and from 2019 onwards, went on a serious drive to grow and improve the business even further. Despite dealing with a drought, they actively explored new markets, and looked for ways to improve their internal systems from management to production, whilst never losing sight of delivering maize meal of the highest quality. The objective was to bring down costs as much as possible in order to be truly competitive in the market.

A major marketing drive was undertaken to compete against numerous competitors, but thanks to a superior product, Buffalo Millers came out on top. That said, the journey wasn't without obstacles, ranging from price wars to compliances that had to be met in various counties.

Here are some of the changes Evans and the Buffalo Millers team implemented along their growth journey:

- Grain handling and storage: To optimise and simplify functions like pest and temperature control, the business switched to an automated silo system. Since it's a computerised system, it also reduced labour costs.

- Human-food interaction: Before the switch to a silo system, product was packed by hand, which required a large number of employees and sometimes caused inconsistency as far as the packed weight of product was concerned. Less human interaction with the maize meal also means less chance of contamination.

- Implementation of a Hazard Analysis and Critical Control Points (HACCP) plan to ensure food safety along every step of the production process, as well as a high-quality product.

- Training staff according to the Kenya Millers Fortification Index (KMFI) as part of the business's commitment to providing fortified maize meal to Kenyan consumers to help prevent malnutrition. Buffalo Millers was awarded the KMFI 2024 Cycle, Millers for Nutrition, Champion Award in recognition for their efforts in this area.

Time to invest in another Roff R-70 Maize Mill

Time to invest in another Roff R-70 Maize Mill

Thanks to their continuous efforts to lower input costs and unlock new markets, the demand for Ufalme maize meal increased to such an extent that Buffalo Millers commissioned another Roff R-70 Maize Mill in 2024. This has brought the company's milling capacity to 200 tons of maize per day.

This has brought the company's milling capacity to 200 tons of maize per day. Having built a successful relationship with Roff Milling over the years, the Roff team was on hand during the two-week installation process to provide training and assistance.

Having built a successful relationship with Roff Milling over the years, the Roff team was on hand during the two-week installation process to provide training and assistance.

The Buffalo Millers team recommends the Roff R-70 Maize Mill for:

- Exceptional extraction rates that put them a cut above the rest, especially since a DGX Degerminator was added to the R-70

- Delivering high quality maize meal that is rated by Kenyan consumers for its colour, taste and aroma

- Economic power consumption compared to other mills in the market

- Easy maintenance and readily available parts

- A compact footprint that meant no new buildings were needed to house the R-70.

Evans Killy's top tips for prospective maize millers:

- Closely study the market in which you plan to operate. Know your future customers' preferences, from taste and colour to texture, and make sure your product meets these needs.

- Choose the very best maize mill you can afford, preferably one that's easy to operate and is energy-efficient. Ensure you can easily find spare parts for the mill in your area. The Roff R-70 Maize Mill ticks all these boxes and more!

- Ensure that your business is compliant with all the relevant laws in your region and has the necessary certificates, etc. in place.

In benefit of the local community

Currently, Buffalo Millers employs 150 people from the Eldoret community and has improved the livelihoods of an estimated 70% of local residents.

It has become such an intrinsic part of the community, that Evans Killy was approached by leaders when unemployment amongst the youth, drug abuse and petty crime became rampant in the area. With financial support from Buffalo Millers, the small local soccer team was invigorated, giving many young men a much-needed purpose. Today, this team is playing in the country's first Division and crime levels in the area have decreased.

Conclusion

As he reflects on Buffalo Millers' amazing journey to becoming one of the biggest maize millers in Kenya, Evans Killy still has many dreams for the future. He would love to see Ufalme sold in all corners of Kenya, playing its part to provide safe, nutritious maize meal to ensure a healthy Kenyan nation. There's also plans to branch out into wheat milling and selling by-products like animal feed.

Says Evans: "I am inspired to keep on growing the business so that I can leave a good legacy behind for my children – built on the belief that dreams can come true through honest, hard work."

Learn more about the Roff R-70 Maize Mill here or contact the Roff sales team on +27 56 212 2697 or sales@roff.co.za

1 comment

Kindly provide a quote for CIF Lusaka for

———

Roff Milling replied:

Hello Christopher, our sale team got in touch via email. Please have a look.