In our previous article, we broke down the basic component of Roff’s crushers – how they work, how they can be applied and their advantages. See the full article here. In this article, we discuss the second option available to millers: hammer milling.

Hammer mill uses

Hammer mills in general can be used to mill almost anything from grains to glass and even plastic. Alternatively, they are used by municipalities to reduce the size of household waste and are very helpful in managing a compost heap around the house. The hammer mill is a nuisance free method of milling and if designed with a specific application in mind, it can mill almost anything that is thrown at it. Because of the simple operation and basic design, the hammer mill is a very cost-effective machine to use.

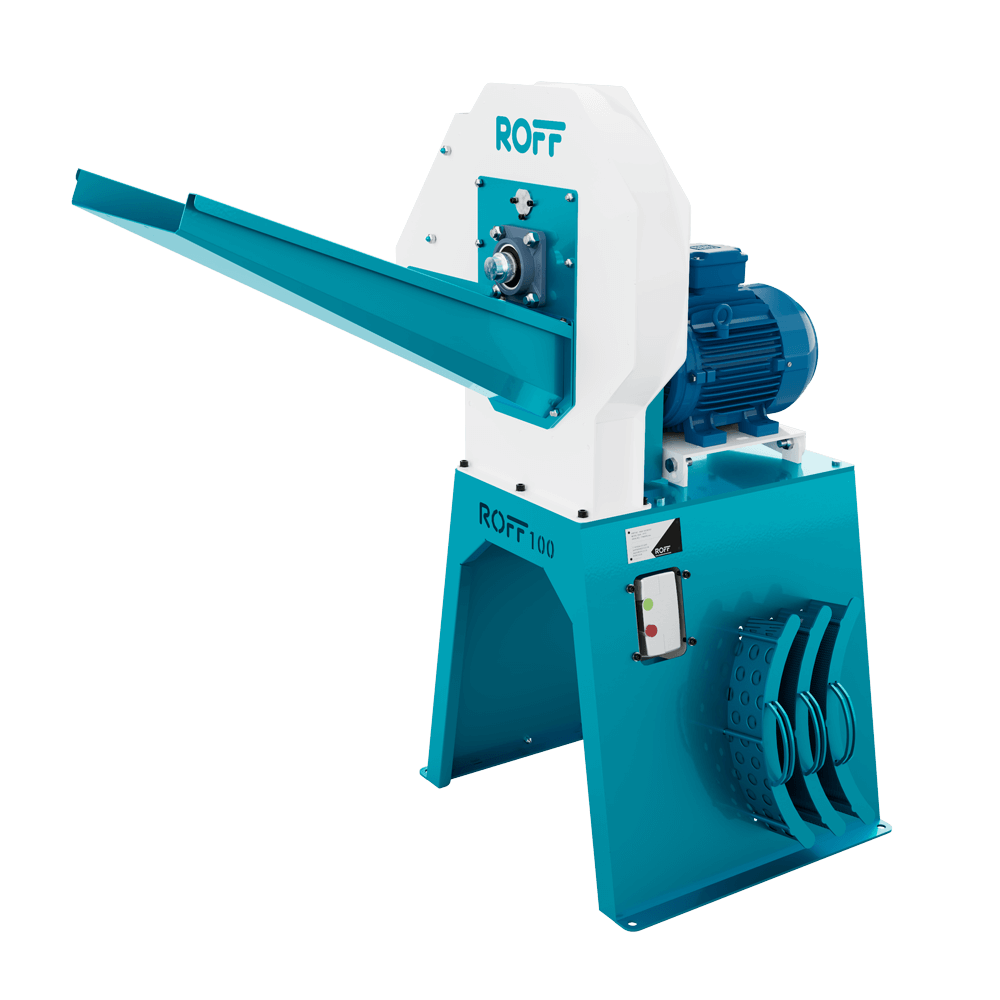

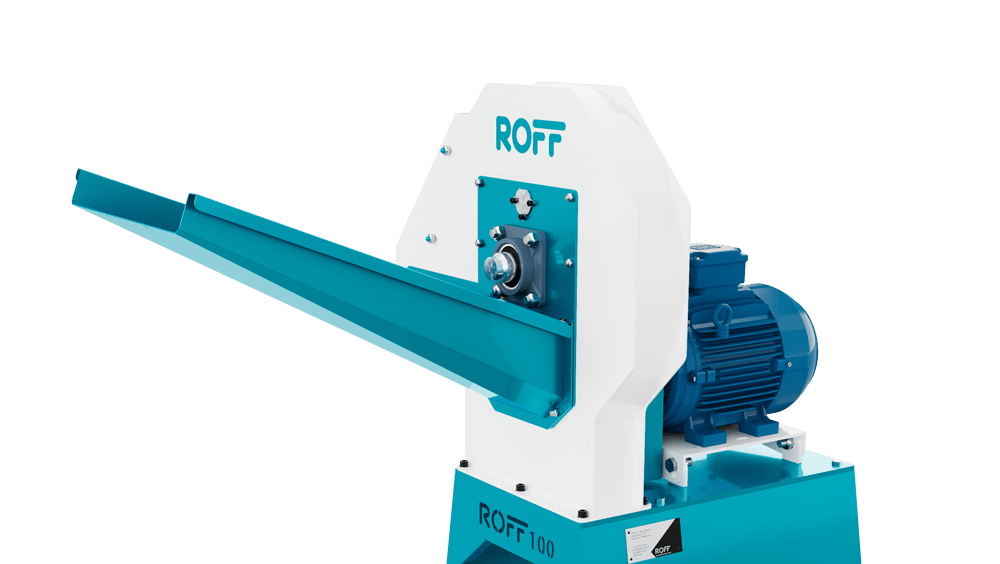

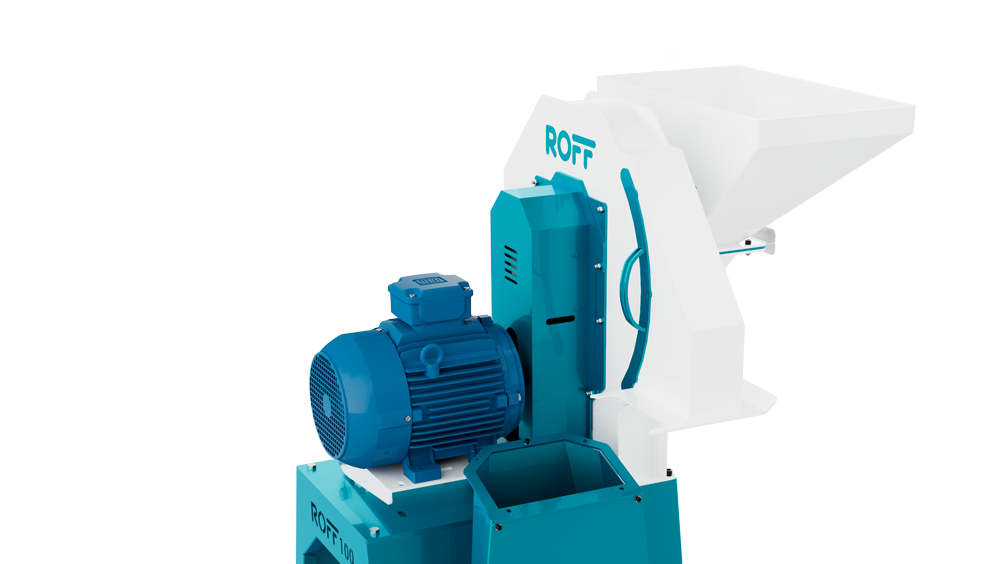

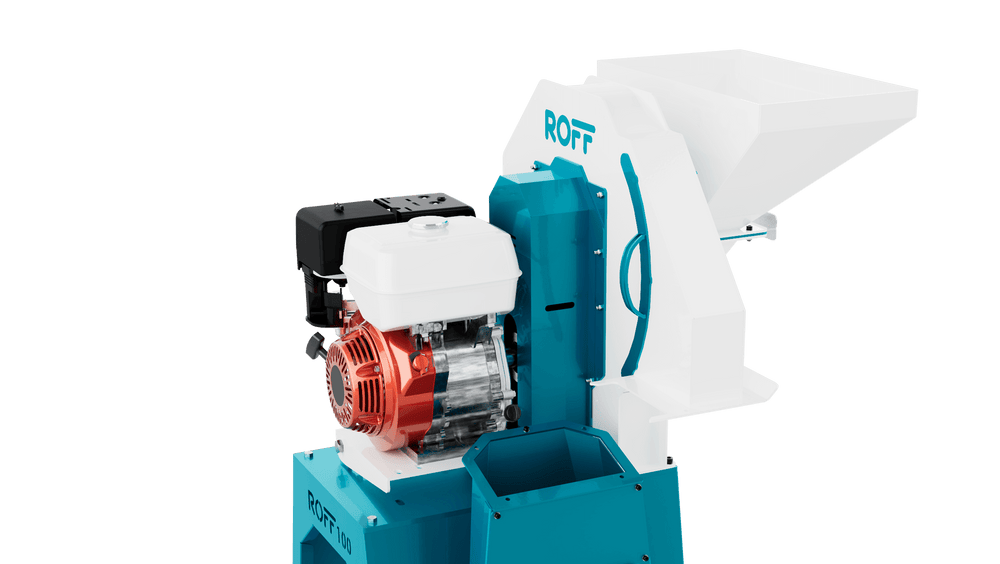

Roff 100 Hammer mill with electric motor

How hammer mills work

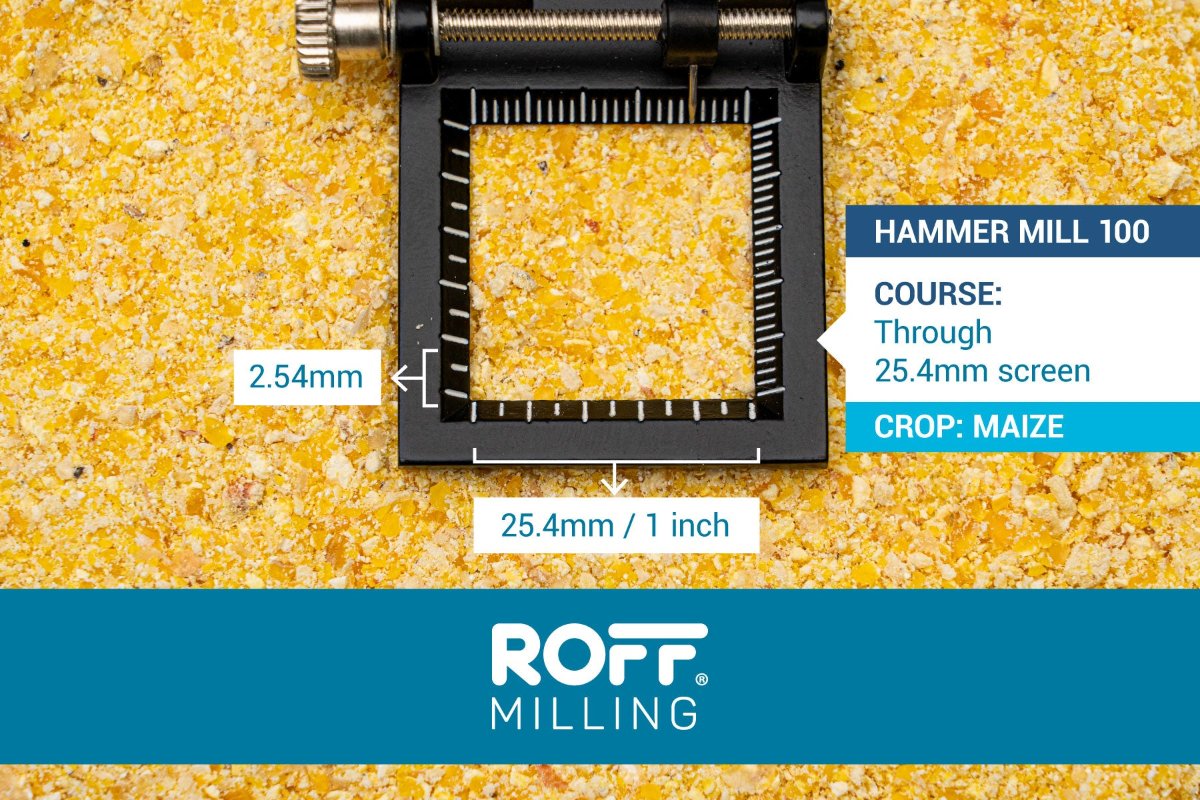

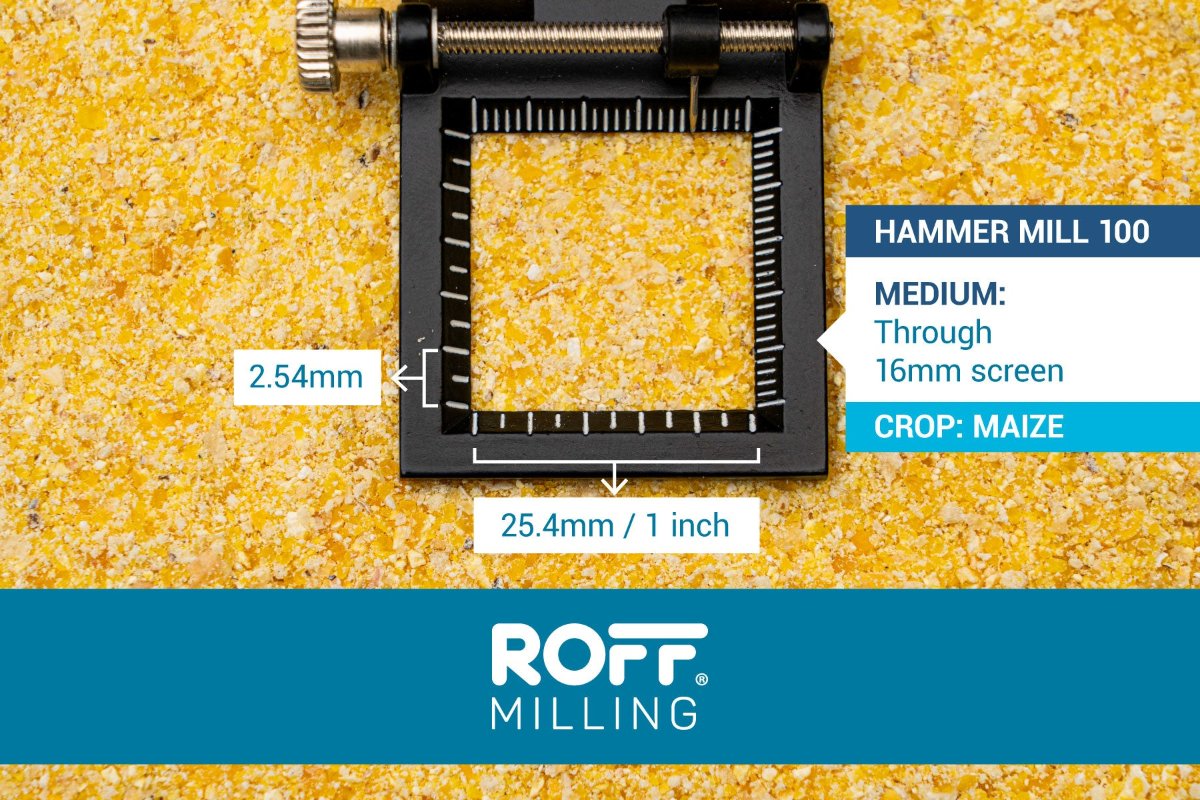

Hammer mills consist of a rotating shaft with hammers attached to it. The hammers rotate at a reasonably high speed close to a milling chamber that is equipped with a screen. The main product is fed into the milling chamber and the hammers mill the product until it has reached a size that is small enough to escape out of the milling chamber through the screen. If the operator wants to change the size of the product, the size of the screen must be changed. Within certain criteria, the same hammer mills can be used to mill grain as well as plant materials such as lucerne.

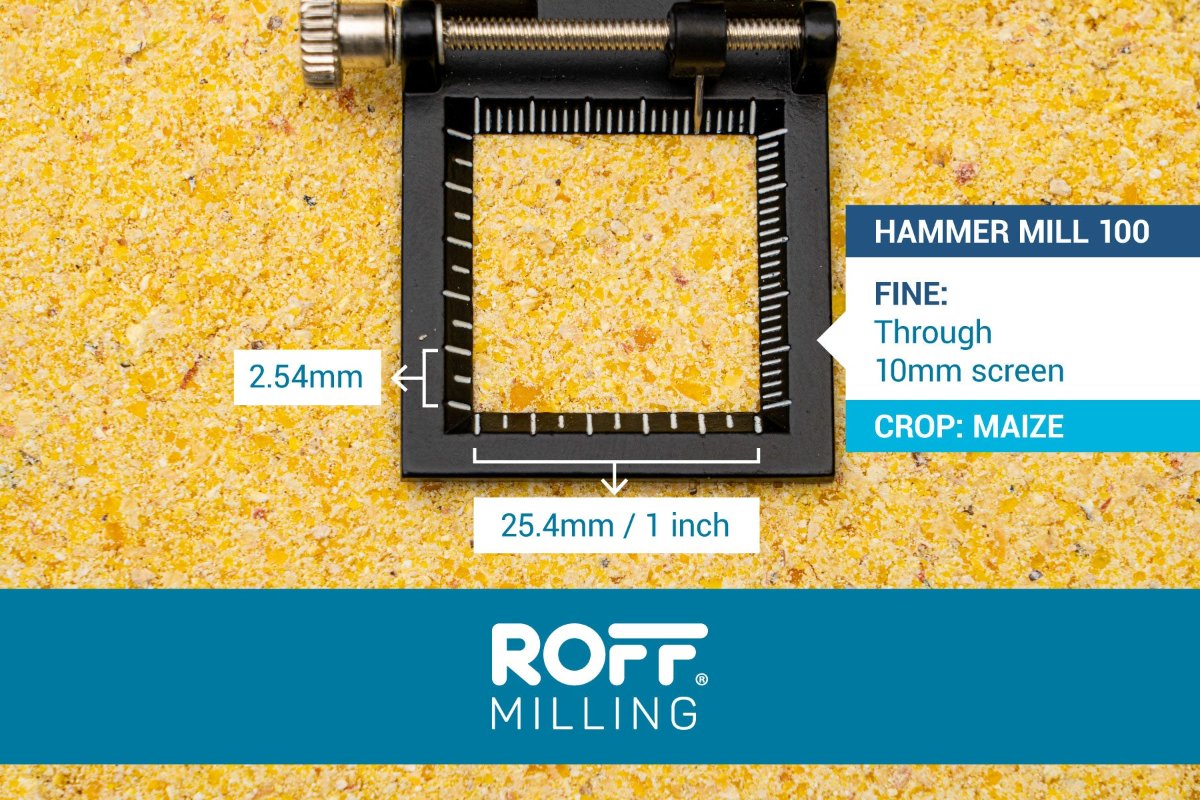

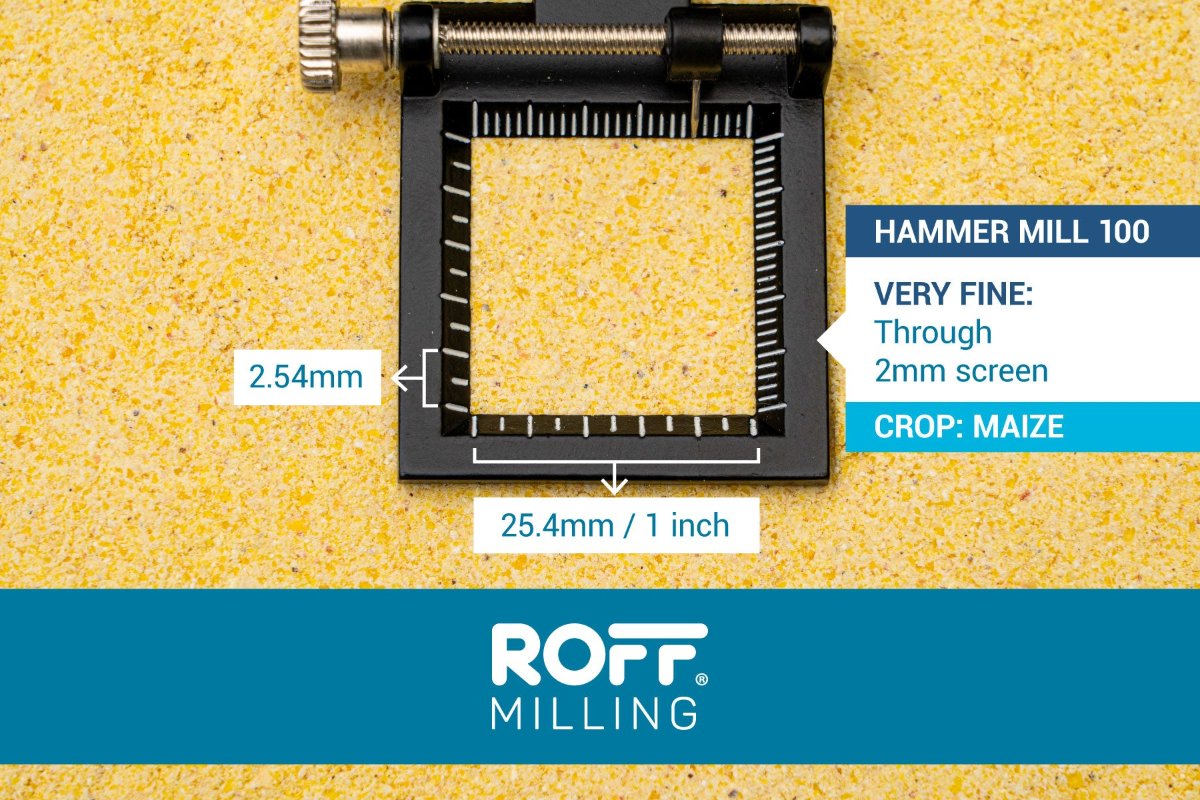

In this aggressive milling process a large percentage of the product will be reduced to a size that is much smaller than the screen size that has been installed in the milling chamber, resulting in a product that is not very homogeneous. If the desired product is very fine, usually below 500 microns, this should not be a problem. However, if the desired product must be, for example, smaller than 2 000 microns, but the feed expert doesn’t want a large percentage below 500 microns, a hammer mill is probably not the best option.

It’s also worth considering that hammer mills are commonly considered to be energy guzzlers and can cause a fairly large kW/ton energy product ratio if not monitored closely. These mills may also be dusty and create an unfavourable working environment if not applied correctly. In spite of this, the hammer mill has its place in milling and is effective when used in the right environment and for the right job.

Roff hammer mills for sale

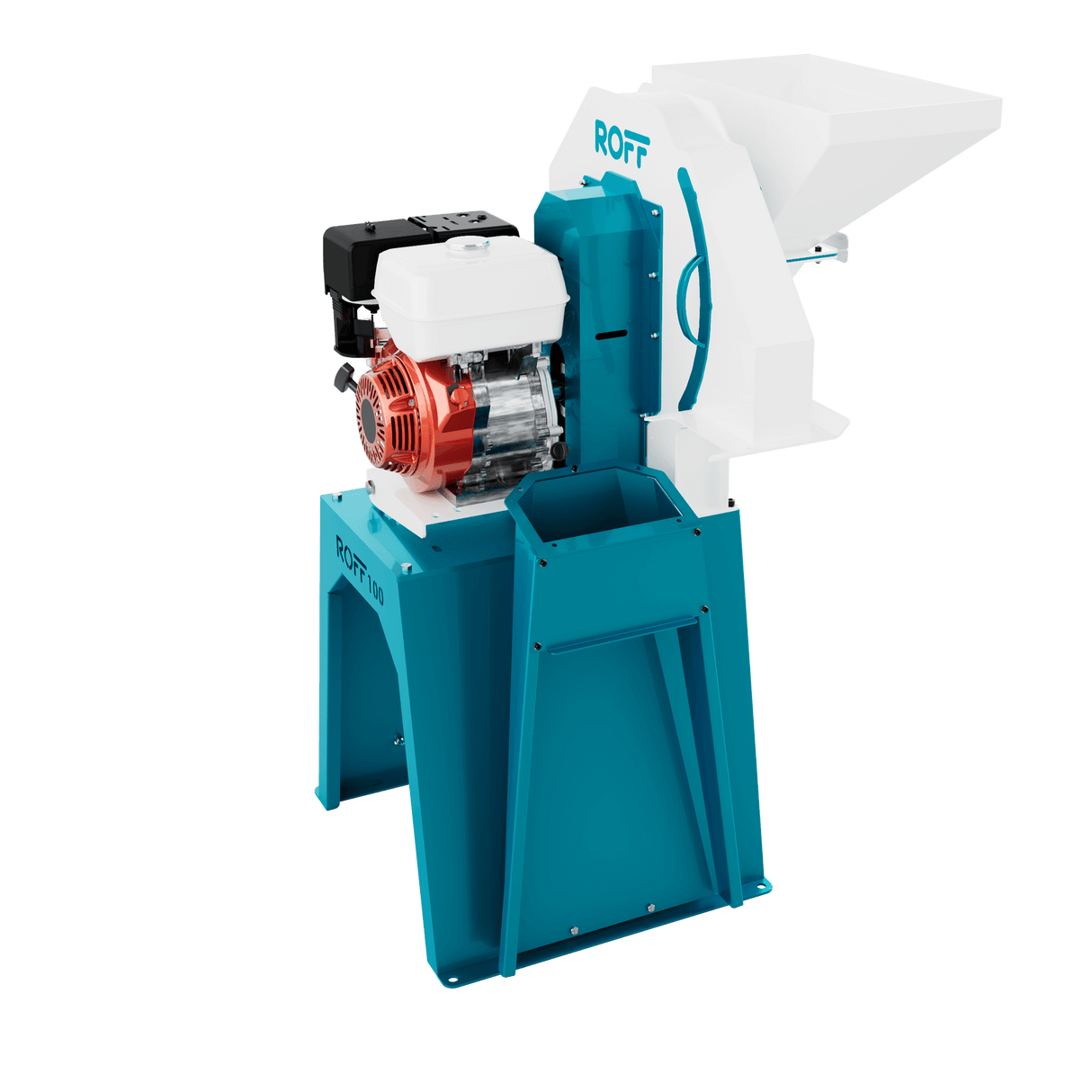

Roff supplies two types of hammer mills and our experts can help you decide which one is suitable for your operation and requirements. The all-purpose Roff 100 is ideal for small operations wanting to mill grain and plant materials for feeding and is also available with the option to use a Honda petrol engine. The Roff 845 is a grain only hammer mill designed for high volume production in a food processing plant where grain product has to be reduced to sizes as low as 250 microns (and larger).

To learn more about Roff’s range of hammer mills, please contact us on sales@roff.co.za or +27(0)56 212 2697.

3 comments

EK ONTVANG NIE OPROEPE TUSSEN 07:00 EN 17:00 NIE.

Watter hamermeule beveel u vir my aan.

Krag bron

- Slegs enkelfase Eskom krag beskikbaar.

- Diesel/petrol enjin aandrywing is ook aanvaarbaar.

- Produk. Maal van gras, mieliepitte en mielie koppe – kop blare, mieliepitte en mieliestrok (die mielie stronk kan hard wees om fyn gemaal te word)

Doel

Die maal van die produkte om as bees, skaap en perde voer aangewend te kan word. (die mielie kop moet fyn genoeg wees om deur beeste en skape geëet te word.

———

Roff Milling replied:

Hello Faf, it looks like you will need a petrol Hammer Mill, you are more than welcome give us a call on 056 212 2697 or e-mail our sales team at sales@roff.co.za<mailto:sales@roff.co.za> for further discussion.

Want a hammer mill

I need hammer mill for production of flour and by product such as bran from wheat .but with smallest harmer mill costing less than R30 000.00