Conditioning is the final stage in the preparation of maize before the milling process. It plays an important role to ensure that finished product is of a high quality, and to achieve the maximum profitability in the milling process, which includes a milling gain.

The three main steps are:

- A controlled quantity of water (measured in litres per hour) is added to the maize.

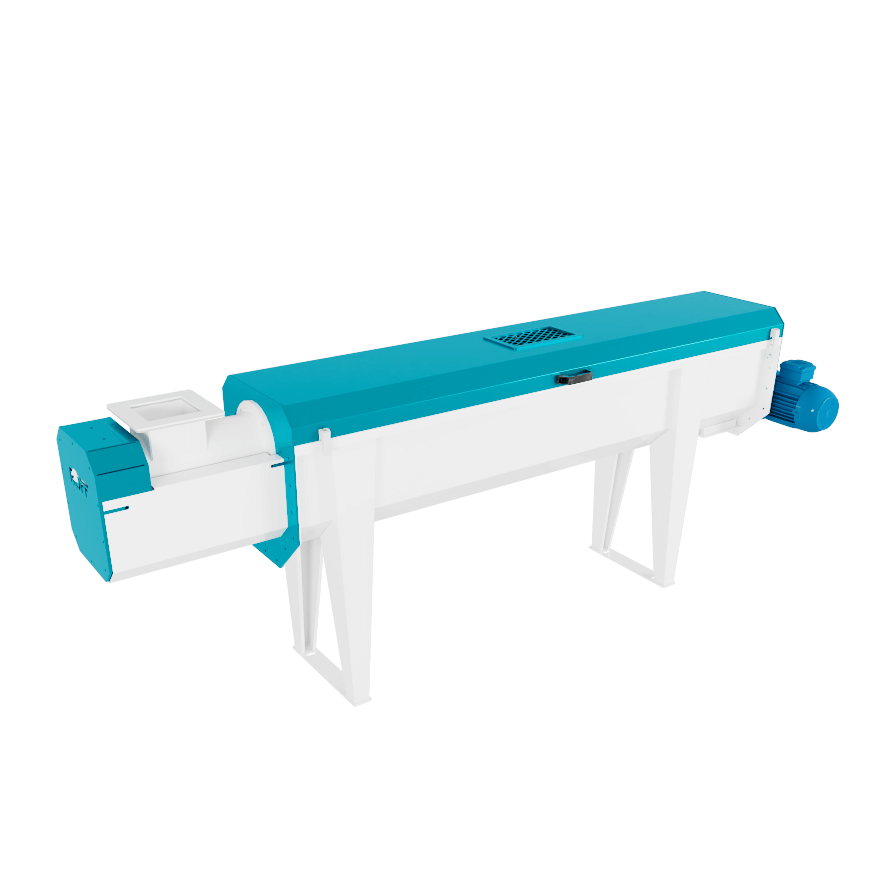

- A controlled amount of maize (measured in kilograms per hour) is mixed with the water using a special dampening conveyor.

- The dampened grain is allowed to rest in a conditioning bin for a predetermined time to enable the water to be absorbed by the maize.

The objectives of conditioning maize

If maize is milled in its dry state without any conditioning, the kernels will be pulverised on the degerminators and roller mills. This will produce a low quality product that’s a mixture of endosperm, germ and bran with low commercial value.

Why condition:

- To toughen the bran skin and make the bran more elastic. The bran should be elastic so it won’t shatter and can be easily removed.

- Toughening the bran will also allow the tip cap to be removed more easily. If the tip cap is not completely removed, it will be ground up on the roller mills causing black specks in the meal.

- To make the germ more pliable or elastic. This will allow for easier separation from the endosperm in one piece. This in turn will stop the fat (oil) from being released into the endosperm.

- To lower the adhesion between the bran skins and the endosperm. This will allow for the bran to be peeled more easily from the endosperm.

- To leave the endosperm as hard as possible. This is very important, since a soft endosperm will result in the manufacturing of a finer meal. Granulation plays a very important role in maize milling, especially in the manufacturing of grits, rice and super maize meal. Mills that produce a high percentage of samp would also require a hard endosperm.

- To increase the moisture for achieving a commercial gain. This is a bonus as the milling gain contributes to the technical profitability of the mill, along with the extraction rate.

Factors influencing the penetration of the water into the maize kernel

- Kernel hardness. Water penetrates the endosperm of soft maize more rapidly than that of a hard endosperm variety. This makes it more difficult to condition soft maize, because if the endosperm is too soft, an excessive amount of fine meal will be produced.

- The initial moisture level. The normal moisture of maize should be between 11 to 12%. Low moisture would be below 10.5%, while high moisture would be in excess of 13%.

- Lying time. The lying or conditioning time controls the depth of penetration of the water into the endosperm. This is a critical aspect of conditioning and will depend on what type of milling process the maize will be subject to (roller mills or degerminators followed by roller mills).

- Temperature. Raising the temperature of the maize by means of hot water or steam, will allow a faster penetration of the moisture into the endosperm. However, this system comes with extra expenses such as boilers, and complicates a fairly simple process.

- Relative humidity. The relative humidity in the area where the maize mill is located (coast or inland) will have an effect on the time the water penetrates into the endosperm. The relative humidity and temperature should also be considered when determining the final moisture of the maize meal. The hotter and more humid the climate, the less the final moisture should be.

Conditioning stages

Water is normally added in two stages. On short systems, a single conditioning system can be used.

- Short systems, single stage conditioning. The conditioning takes place after the maize has been cleaned and all the impurities have been removed. Between 6% and 8% moisture is added, and the maize is allowed to lie for approximately 10 minutes, depending on the kernel hardness. Obviously the softer the kernel, the shorter the lying time as the endosperm must remain as hard as possible for aforementioned reasons. The water that’s added should not penetrate the endosperm and is only to loosen the bran from the endosperm.

- Double conditioning. Here, two conditioning stages are used. Moisture is added according to the calculation below, and the maize is allowed to lie for 3 to 12 hours, depending on the kernel hardness and mill design. In the 2nd conditioning stage, an addition of 6% to 8% water is added with a short lying time of 10 to 20 minutes. The moisture must not penetrate into the endosperm, as this would make it too soft. The moisture must mainly be just under the bran and germ layers so that the bran/germ can be easily removed (almost like peeling a banana).

Maize with a moisture content higher than 13.5% should not be milled, and the miller should ensure that the moisture content of maize meal should never exceed 14%.

Read the next installment on The importance of maize conditioning: Part 2, where we cover the equipment used during conditioning and also include a handy calculation.

7 comments

The milling process in some companies maize grain is not left to rest,

and why is it that for yours is put in a bin for some time before milling.

———

Roff Milling replied:

In certain cases, a double conditioning system with a conditioning bin can have advantage of moisture addition to final product.

Very helpful on maize conditioning

Do you provide tutorials on maize milling?

———

Roff Milling replied:

Hello Ntsukunyane, when purchasing a Roff maize mill, upon installation, training can be provided. If you request any additional information, please do not hesitate to contact us on sales@roff.co.za<mailto:sales@roff.co.za>. Regards

A very helpful information on conditioning of maize.

———

Roff Milling replied:

Thank you for the feedback.

+256774850725

+256752579226

———

Roff Milling replied:

Thank you for the information, our sales team will get in touch shortly.

This is very helpful i would like to learn more about maize milling

———

Roff Milling replied:

Hello, you can contact our sales office at sales@roff.co.za<mailto:sales@roff.co.za> for further information and assistance on maize milling.

Good content of information on the milling of maize