In food processing and FMCG plants, it’s rarely the “big machines” that cause the most frequent headaches — it’s the small wear parts and consumables that quietly decide whether the line runs smoothly or becomes a constant stop-start.

Mesh is one of those components. When the mesh is right, it protects equipment, supports product consistency, and helps keep hygiene standards on track. When it’s wrong (or worn), it can create quality drift, contamination risk, and unnecessary downtime.

Where mesh fits into the food and FMCG production line

Mesh is commonly used for:

- Screening and separation of raw materials and powders

- Sifting to control particle size

- Protecting downstream equipment from oversize material and contaminants

- Supporting quality control by improving consistency across batches

Common applications include grains, flour, sugar, spices, powders, and similar ingredients.

1) Screening and separation: protect the process before it becomes a problem

A screening step is often your first line of defence. Mesh helps remove oversize particles, clumps, debris, and unintended foreign matter. That matters because every contaminant you catch early is one less chance of damaging equipment, blocking flow, or introducing variability into the final product.

2) Hygiene and cleanability: why stainless is the default choice

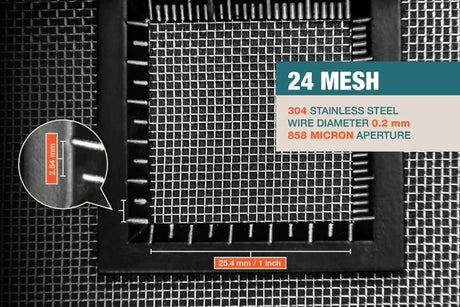

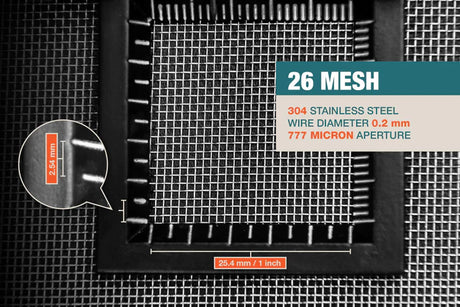

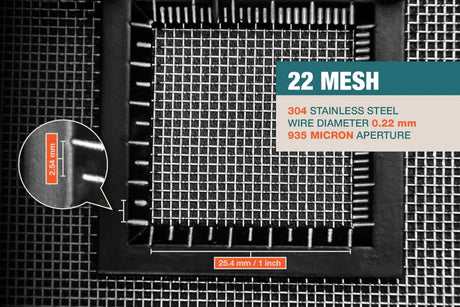

Food and FMCG plants live by one rule: clean, then clean again. Stainless steel mesh (especially 304 stainless) is widely used because it supports wash-down routines, and frequent handling without degrading like plastic alternatives. Just as important, a well-specified mesh helps reduce product build-up, making clean-down faster and more consistent.

3) Consistency and quality control: texture, taste, and pack accuracy start with particle size

Uniform particle size directly affects texture (mouthfeel), mixing behaviour, taste perception, shelf stability, and packing accuracy through better flowability and fill consistency. Mesh selection is one of the simplest levers you can pull to keep product specs stable across shifts and batches.

4) Throughput and uptime: mesh that blocks flow will steal your production time

A plant can lose hours to blockages, frequent rework, repeated stop-start cleaning, and inconsistent screening performance. Correct mesh sizing helps material flow smoothly, reducing bottlenecks and unplanned pauses.

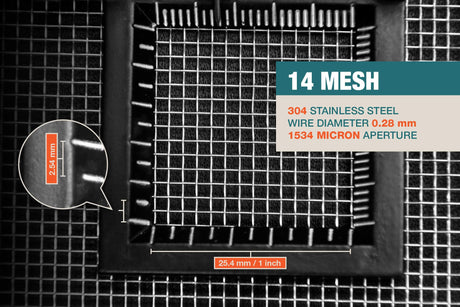

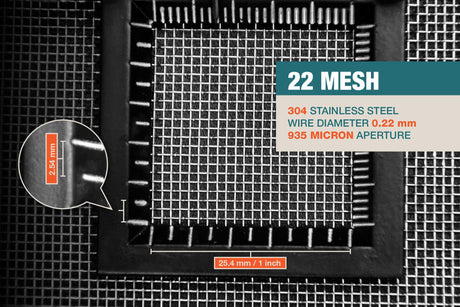

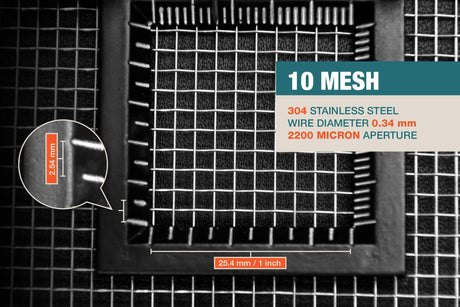

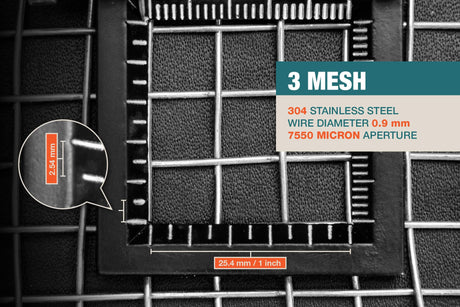

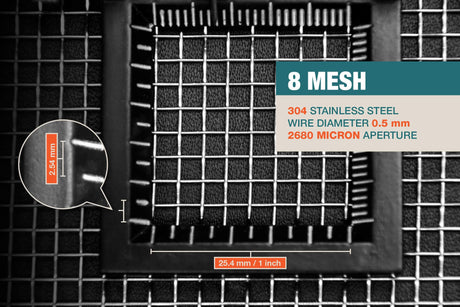

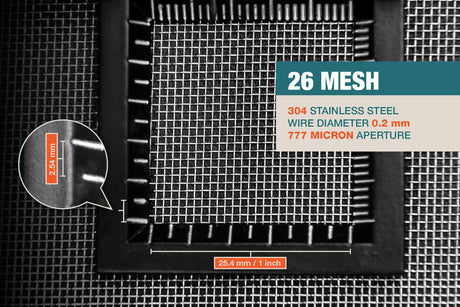

Mesh selection guide for food and FMCG teams (the practical version)

Mesh selection guide for food and FMCG teams (the practical version)

When you’re selecting mesh for screening/sifting, you’re balancing four things:

- Target cut point (what you want to remove / what you want to keep)

- Flow rate (too fine can slow throughput)

- Durability (wire thickness and handling)

- Cleanability (how easily you can wash down)

If you tell us the product type (flour, sugar, spice, grain), desired separation point, and the screen format, we can recommend a suitable mesh size range.

What to look for when replacing mesh

- Visible deformation: stretched sections change your separation result

- Broken wires: contamination risk and inconsistent screening

- Permanent clogging: even after cleaning, the mesh doesn’t “open up”

- Unexplained quality drift: particle size or flow changes often trace back to worn screens

FAQ

Quick answers to common questions about stainless steel wire mesh in food processing and FMCG environments.

Is stainless steel mesh suitable for food contact environments?

Stainless steel is widely used in hygiene-critical industries and is easy to clean.

Do you stock different mesh sizes for different products?

Yes — mesh is commonly supplied in a wide range of sizes depending on the screening goal.

Can we order from Zambia for local projects?

Yes — Roff’s Zambia branch in Kitwe can assist with mesh availability and selection.

Get the right mesh for your plant

- Shop stainless steel woven wire mesh (screening/sifting)

Available from Roff South Africa and from the Roff Zambia branch in Kitwe (Unit 3, Vibhav Business Park, Chingola Road, Garneton, Kitwe). Contact the team for the best-fit mesh size for your product and throughput.