Worldwide about 25% of all stored grain, such as maize, is lost annually to damage caused by insects, which makes fumigation a necessity.

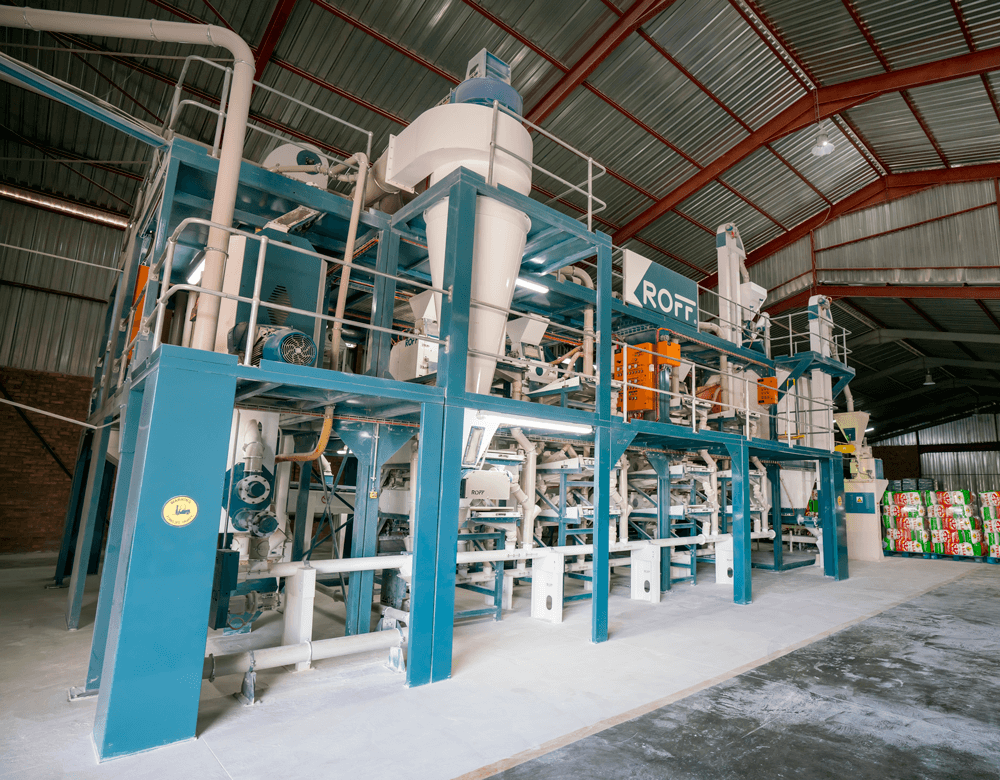

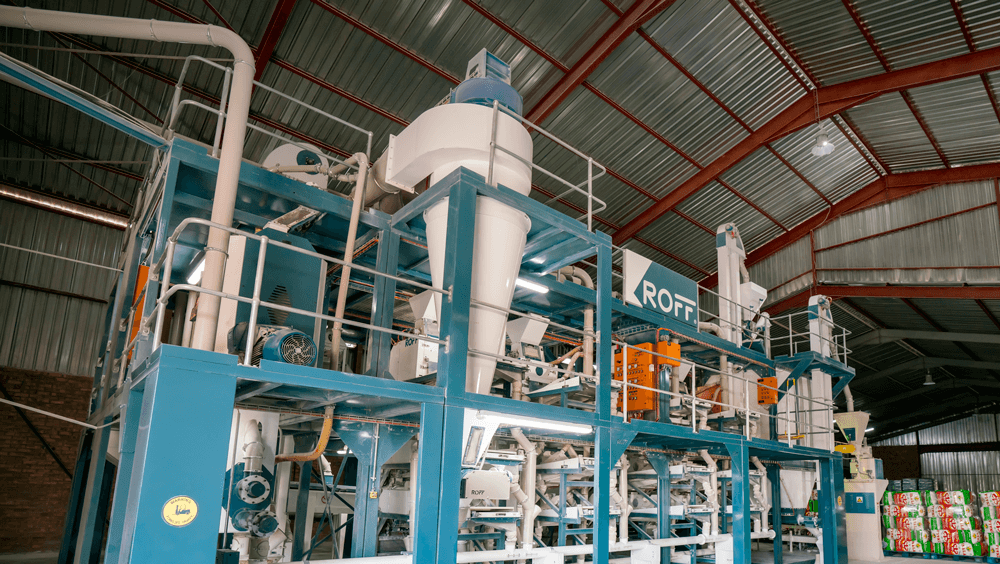

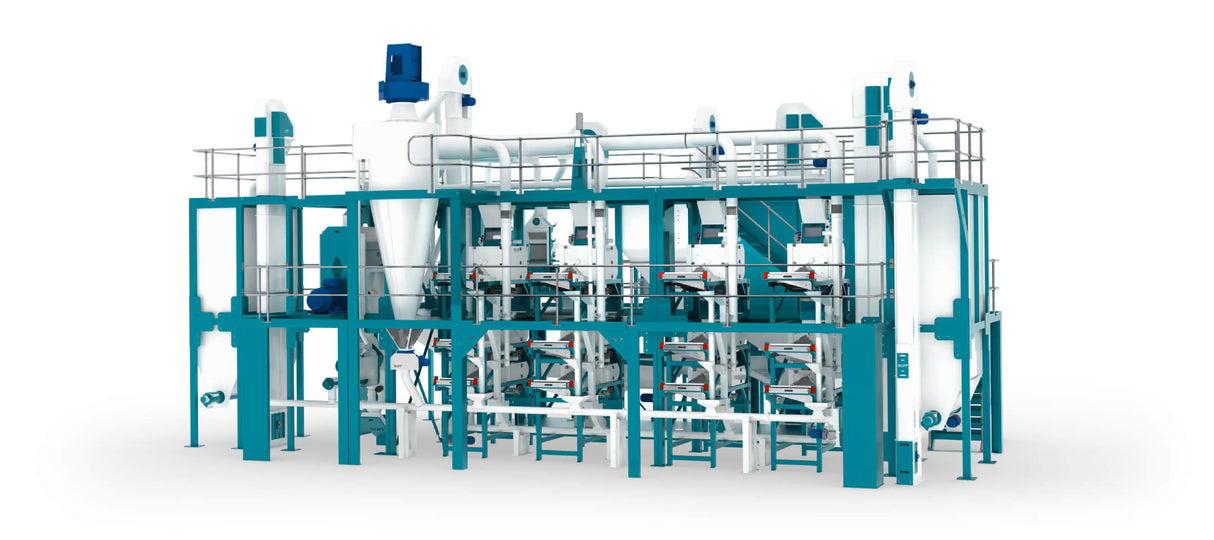

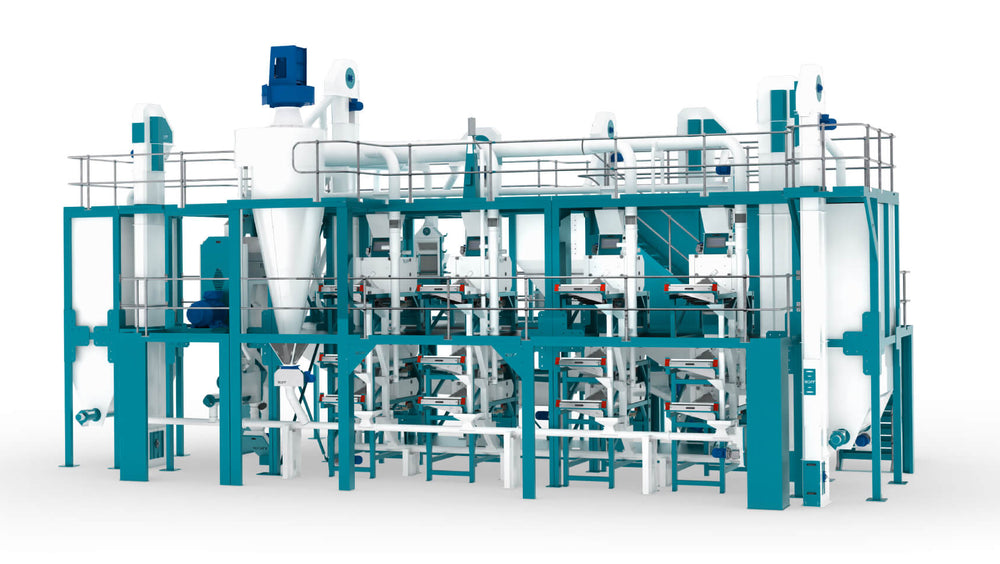

In this four-part series, Roff takes a look at measures the maize miller can take to control this very real threat to his business. This blog explores how to control insect infestation at the maize mill.

The two main control measures to eradicate insects on the maize milling site are cleanliness or good housekeeping and regular fumigation.

01. Housekeeping

Serious infestation problems are seldom found in a clean and well-maintained mill where the standard of housekeeping is good.

A high standard of cleanliness can be achieved by well-planned daily, weekly and monthly cleaning schedules implemented by the mill management. This schedule includes the following:

- Remove dust continuously.

- Prevent dusty conditions (e.g. leaky spouting).

- Keep the premises clear of undisturbed breeding and feeding areas where insects can multiply and then find their way into the silo or mill buildings.

- Do away with crevices and ledges by filling them with concrete.

- Destroy any material such as sweepings and screenings which are infested.

- Fumigate all returned stock from customers before mixing them into the mill.

Insects love the warm and moist conditions inside machines, conveyors, etc., where they can breed. The webbing created by moths as part of their breeding cycle causes chokes in spouts, and builds up behind the feed gates on the roller mills. It’s vital that, as part of the planned maintenance programme, the mill is stopped so that these areas can be cleaned out.

02. Chemical insecticides

There are many types of chemical insecticides available for the control of infestation, but it’s vital to use those which are officially approved by the milling industry.

All insecticides and fumigants are toxic, and a health hazard. Therefore, the precautions recommended by the manufacturers must be strictly adhered to, and the necessary protective clothing must be worn when applying them. Only mill personnel who’ve been trained in fumigation should administer fumigants and insecticides.

For pesticides to work, they must:

- Be in contact with the insect.

- Be absorbed by the insect, either through the skin or the air passages.

- Remain stable in the insect’s body until it’s had the desired effect.

- Impair one or more important bodily function which will result in the death of the insect.

Did you know?

The use of methyl bromide as a fumigant is being actively phased out due to its negative effect on the ozone layer. It’s highly toxic and should only be used by a fully trained person.

Visit roff.co.za to explore Roff’s range of maize milling machines, milling equipment and milling accessories, or contact us on sales@roff.co.za or +27 56 212 2697.