Of the many Roff clients who sing the praises of their Roff R-70 Maize Mills, brothers Zakariya, Yoonus and Mohammed Hanif Chiboo might just be its biggest fans. They use not one, but five R-70 Mills in their Yarona Milling operations, after all!

In this blog we share the Yarona Milling success story: a true testament to the value of perseverance and partnering with the right team for advice and support.

Family ties to agriculture

In the early 1900s, the Chiboo brothers’ great grandfather arrived in South Africa from India and settled on the farm Hartebeesfontein. Their father was one of the first Indian farmers in the former Transvaal province, so one could say that farming is very much in this family’s blood.

In 1979, Mr Chiboo Senior started renting premises in Syferbult from which to run Crossing Grocers, a wholesale store. He bought the property in 2002, and today Yarona Milling is also located there.

In 1979, Mr Chiboo Senior started renting premises in Syferbult from which to run Crossing Grocers, a wholesale store. He bought the property in 2002, and today Yarona Milling is also located there.

From a young age, the Chiboo brothers helped out in their father’s store over weekends and during the school holidays. To grow up serving customers behind the cash register taught them sound business principles in a practical manner. In this way, their father gave them a brilliant foundation for their later years as maize milling entrepreneurs.

From pipe dream…

The Chiboo brothers initially produced maize as smallholder farmers, but were looking for ways to make more money since farming is a high-risk sector without big profit margins.

They started throwing business ideas around with their late business partner Charles Easton, a successful farmer in the Magaliesberg area at the time. Together they visited the NAMPO agricultural expo, looking for ideas and inspiration and seeing the maize milling equipment on offer.

Since they couldn’t afford to buy brand new maize milling machines, they approached their uncle whose milling machines were just gathering dust in the storeroom, and offered to take these off his hands. Many of these machines were old Roff maize milling machines, bought on auction and/or second-hand.

As such, the brothers carried on farming, but hit a tough patch when they experienced drought for three consecutive years from 2011 to 2013. They finally had to give up and start from scratch, after selling off their sheep to pay off the farm’s debts.

… To a new beginning

Finally in 2014, the Chiboo’s uncle agreed to sell them his milling equipment. But once the brothers’ operations were up and running, they only managed to produce around 80% chop and 20% maize meal on their set-up. It didn’t make any financial sense to continue along this path.

Read here why extraction rates play such a key role in the maize miller’s profitability.

Read here why extraction rates play such a key role in the maize miller’s profitability.

Meeting Roff makes all the difference

After noticing the Roff logo on their existing maize milling equipment, the Chiboo brothers decided to make contact with Roff Milling. They saw the R-70 Maize Mill on offer, but couldn’t afford it at the time, so asked Roff for assistance with servicing their old machines instead.

Roff’s technicians visited the premises, sharpened the rollers on the existing mill and gave advice. The brothers followed this advice in stages due to financial constraints. Their first priority was to produce good maize meal and samp for their small base of loyal clientele.

Roff’s technicians visited the premises, sharpened the rollers on the existing mill and gave advice. The brothers followed this advice in stages due to financial constraints. Their first priority was to produce good maize meal and samp for their small base of loyal clientele.

They started with an inlet capacity of 500kg per hour, and an outlet capacity of 350kg per hour.

Moving on to the R-70

The brothers continued growing Yarona Milling, having to frequently add capacity by buying additional Roff equipment. This however took up a lot of warehouse space, and building a brand new warehouse would be expensive and time-consuming, so they started considering alternatives. They noticed that many competitors were using high-end European equipment which also came with a hefty price tag.

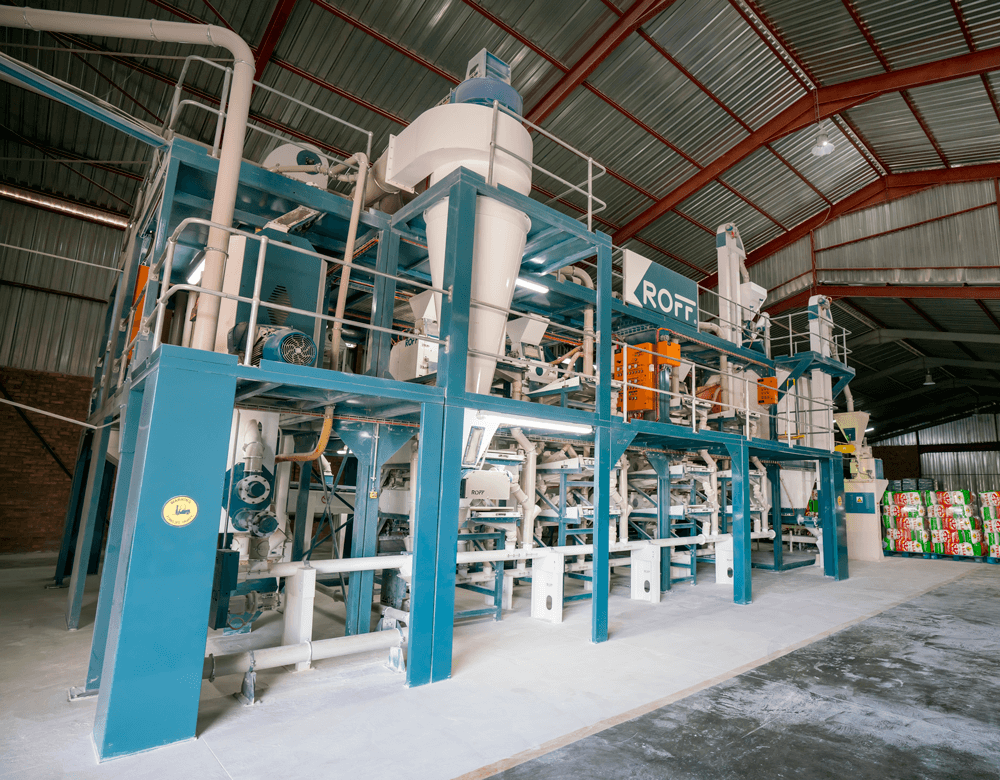

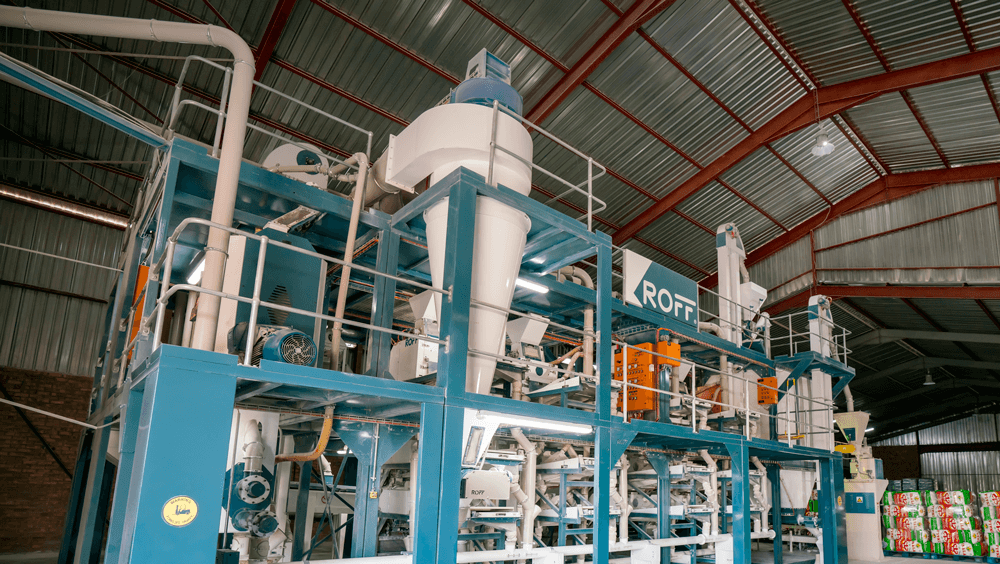

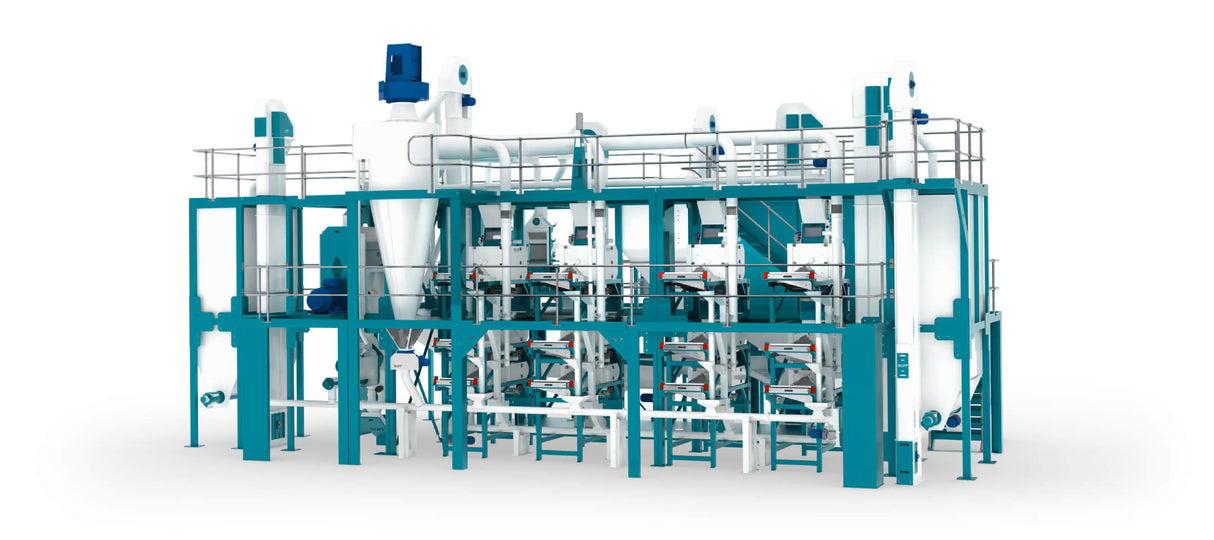

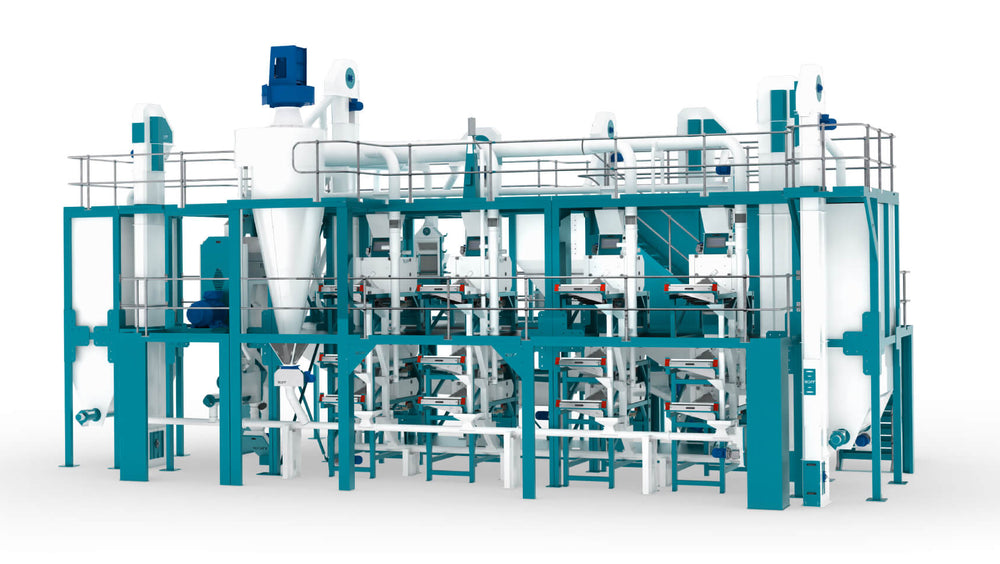

The Roff R-70’s small footprint plus its capacity and best-in-class extraction rates compared extremely favourably with what was on offer internationally, and at a competitive price since its locally manufactured, so the brothers invested in their first Roff R-70 Maize Mill.

The rest as they say is history, and today, Yarona Milling has five R-70 Maize Mills in operation!

Says Zakariya: “We’re getting a phenomenal product out of the R-70 – it speaks for itself. Our maize meal sells out fast in the wholesale space. The R-70 is a straight run machine, which helps us to contain costs. In turn, the consumer gets a good product at a very reasonable price. The R-70’s extraction rates allow us to sell our 12,5kg bag of meal for R20 less that the bigger brands, while still making a good profit.”

He adds that they would rather invest the money potentially spent on costly European machines into their business, and avoid inflating the price of their maize meal.

Currently, Yarona Milling boasts an impressive 20-ton per hour capacity (on their five R-70 machines combined).

Currently, Yarona Milling boasts an impressive 20-ton per hour capacity (on their five R-70 machines combined).

Zakariya reflects: “We can’t believe where we started and where we’ve gone. We count our blessings and thank everyone who assisted us… Roff Milling in particular. We ‘argued’ until we found solutions, so we don’t regret sticking with the Roff team. We will buy another R-70 in a heartbeat!”

Watch the inspiring story of Yarona Milling:

3 comments

May I stock this chiboo maize meal I want 5 pallets

———

Roff Milling replied:

Good Day, Roff is a maize mill manufacturer, we do not supply the maize itself. Regards

I am interested in the maize milling machine, R-40 :2-3 tone/ hr capacity.

However, I want to know its MOTOR capacity in terms of horse powers (HP) used to run the whole machinery.

I look forward to hearing from you soon.

Best regards,

Majid Nyanzi

Uganda, East Africa

———

Roff Milling replied:

Hello Majid, our sales team will get in touch soon, in the meantime, have a look at the brochure https://www.roff.co.za/pages/r-40-maize-mill

My name is Abraham Banda (Director) Rhema Manufacturers and General Dealers Limited . I watched a video for your machines and I am interested to know more about the machines

———

Roff Milling replied:

Hello Abraham, our sales team will get in touch shortly. Kind Regards

———

Roff Milling replied:

Good Day, please refer to your e-mail inbox, our sales team has been in touch. Regards